New Thin Thread Technology for Light Alloys

Benefits

High joint-strength

Safety against dynamic loads

Consistently high clamp loads

Self locking vibration resistance

Easy lead-in, low drive torque

Opportunity to reduce installation depth

Compatible with metric machine threads

ALtra Calc Software validates applications, speeding up engineering development time

Features

The small 33° flank angle of the ALtracs® Plus creates a stronger female thread in the mating material.

Circular body shape provides a larger area of thread engagement

Tapered thread forming lead-in with sharp-crested threads

Thread compatibility - the ALtracs® Plus thread is designed to be completely interchangeable with metric machine thread

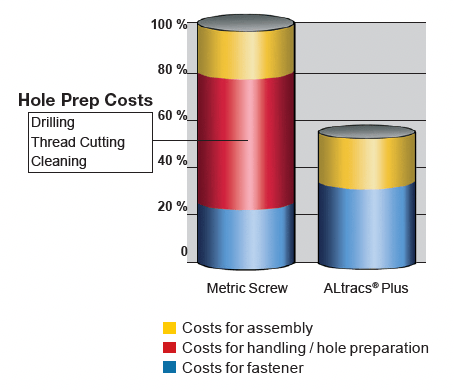

Cost & Design Savings Advantages

ALtracs® Plus vs. Machine Screw

Compared to machine screws, cost savings of up to 40% can be achieved with thread-forming fasteners. Self-tapping fasteners can be directly assembled into cast holes as opposed to the pre-drilling, thread tapping, and subsequent cleaning of metal chips to prepare the hole to receive a machine screw.

All these costs for hole preparation can be saved.

Characteristics, Benefits, and Features

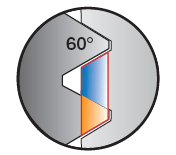

60º Thread

The 60-degree flank angle of a standard thread forming or machine screw has reduced the shear area between threads.

The 60-degree flank angle of a standard thread forming or machine screw has reduced the shear area between threads.

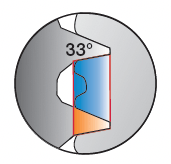

ALtracs® Plus Thread

The unique ALtracs® Plus thread geometry provides greater shear area between threads, resulting in higher pull-out and strip-out performance.

The unique ALtracs® Plus thread geometry provides greater shear area between threads, resulting in higher pull-out and strip-out performance.

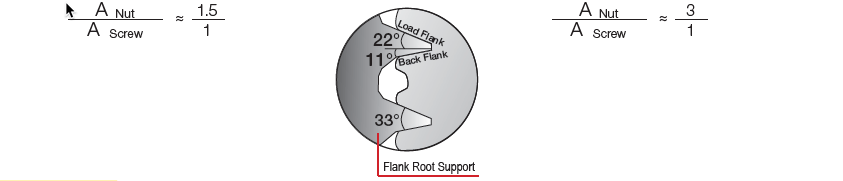

Flank Geometry

The smaller 33-degree flank angle of the ALtracs® Plus fastener creates a more robust internal thread in the mating material than screws with a 60-degree flank angle—the larger tooth area of the female thread results in a more robust joint. The asymmetric flank design optimizes material displacement during the thread-forming process and ensures maximum thread engagement. The profile of the lower thread flank delivers increased strength, which is critical for high-load joints.

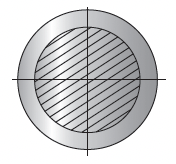

Thread Cross Section

The round body shape provides greater thread engagement than trilobular fasteners and improves the clamp retentioetter's long-term joint behavior.

The round body shape provides greater thread engagement than trilobular fasteners and improves the clamp retentioetter's long-term joint behavior.

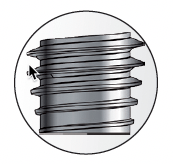

Thread Forming Region

The tapered thread forming lead-in with sharp-crested threads helps to minimize debris generation and lowers drive torque.

The tapered thread forming lead-in with sharp-crested threads helps to minimize debris generation and lowers drive torque.

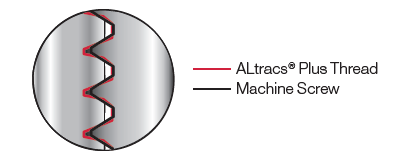

Thread Compatibility

The ALtracs® Plus is designed to be completely interchangeable with machine screws. Therefore, ALtracs® Plus can be used in existing tapped machine screw threads of the same size, or alternately, a machine screw of the same size can be used in the thread formed by an ALtracs® Plus fastener, eliminating any field service concerns.

Design Guidelines

Material

ALtracs® Plus fasteners are manufactured from carbon steel and neutral hardened to HRC 33-39.

Alternate materials are available upon request.

Coatings & Platings

A wide variety of plating and coating options can be applied to meet specific customer requirements for corrosion resistance and joint performance.

Lubrication

Lubrication is suggested for all thread-forming applications in light metals. Contact our Sales or Engineering Services team for recommendations.

Special / Examples

ALtracs® Plus fasteners can be manufactured with many popular internal and external drive systems to meet assembly requirements.

Theoretical Assembly Parameters

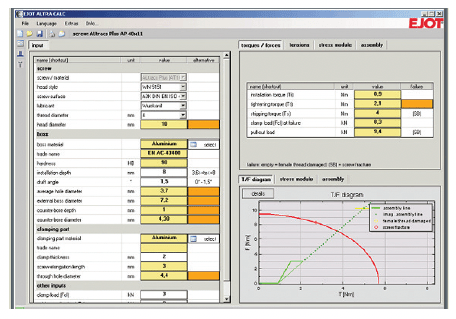

ALtra CALC validates applications, reducing engineering and development time and cost.

- Application and test assembly examples populate the database

- Parameters help the designer to understand the predicted joint behavior of the ALtracs® Plus fastener