Versatility in Particle Board and Plastic Applications

Benefits

Assemble into multiple materials with one thread design

Slim root diameter and low thread angles for lower installation torque

Minimized material splitting

Greater pull-out resistance

Features

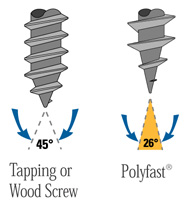

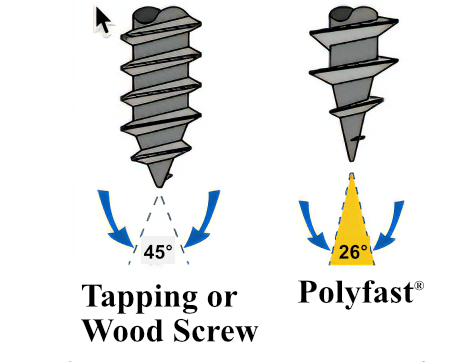

45° asymmetrical thread

26° point for lower end-load to start

Slim root diameter

Inch and metric sizes

EXCEPTIONAL PERFORMANCE AND VERSATILITY… THE POLYFAST® WAY

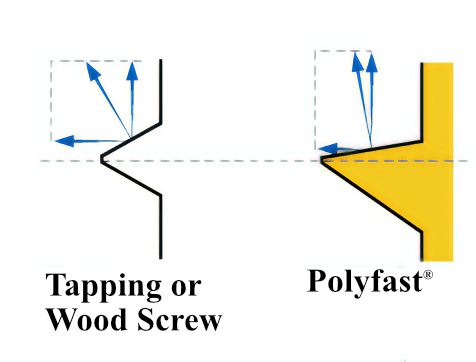

Polyfast® fasteners are unique thread designs that perform exceptionally in plastic and particle board applications. The asymmetrical thread form and low root diameter provide lower installation torque and efficient fastening. In plastics, this thread design minimizes radial stresses and excessive material displacement, which increases the potential for material cracking. The wide-spaced threads of the Polyfast® design allow additional material to flow between the threads, resulting in higher resistance to pullout forces.

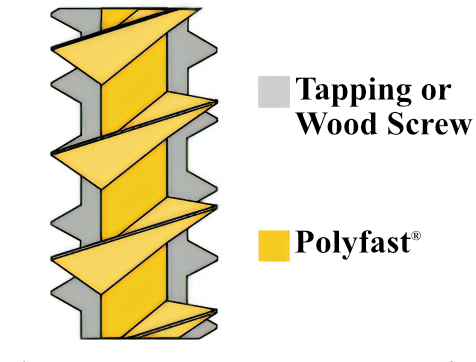

POLYFAST®— ASYMMETRICAL THREAD

DESIGN & PERFORMANCE

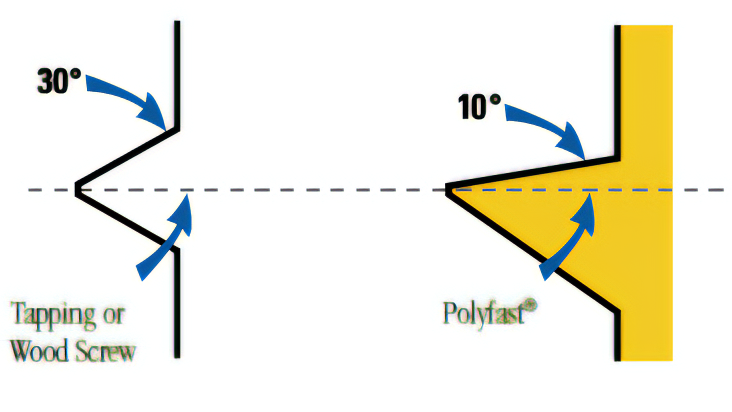

- Slim root diameter and low angle of thread reduce installation (drive) torque required.

- Minimizes radial stresses generated during thread forming.

- Asymmetrical thread form efficiently maintains clamp load while minimizing the radial stresses generated.

- High thread profile and unique thread form provide a greater surface area on the thread flank for load distribution.

- Large pitch and high thread profile maximize resistance to pull-out forces.

- Round body design eliminates areas of high stress relative to the fasteners' overall cross-section.

- Gimlet point designs provide unique fade-out thread for optimum starting of the fastener.

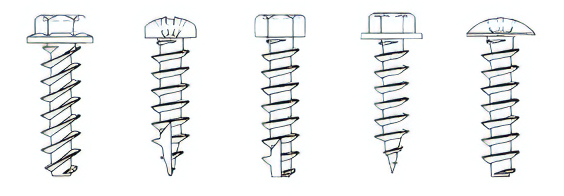

THE CHOICE IS YOURS

- Exceptional performance in plastic and high-density particle board.

- Asymmetrical or symmetrical thread designs.

- Blunt or Gimlet point configuration.

- Inch or metric.

- Shank slotted for certain applications.

- Full line of licensed drive systems.

45° Thread Angle

- Slices cleanly

- Less material distortion

- Minimizes splitting

Slim Root Diameter

- Minimal material displacement

- Greater pullout resistance

- Low installation torque

- Higher strip out torque

26° Point Angle

- Easier starting

- Fadeout thread

- Minimal end load

Additional Family Products