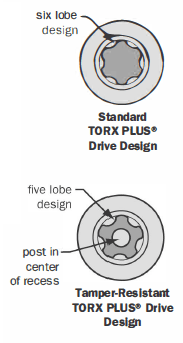

Security Drive System

Benefits

Allows optimum torque transfer and increased drivability

Allows improved productivity on the assembly line

Non-symmetrical shape provides increased resistance to tampering

Limited access to drivers maintains integrity of system

Features

Non-symmetrical, elliptically-based geometric configuration

Five lobes with solid post in center of recess

Drivers only available to OEM's and authorized service personnel

Manufacturers worldwide are discovering how the TORX PLUS® Drive increases torque transfer, extends tool life, and increases productivity on their assembly lines. Now, these benefits are available in a unique tamper-resistant version. When combined with a countersunk or button head design, the tamper-resistant TORX PLUS® fastener is extremely difficult to remove without the proper tool.

PROVIDES RESTRICTED ACCESS TO ANY APPLICATION

The tamper-resistant TORX PLUS® Drive offers restricted access in the field along with all the assembly benefits of the TORX PLUS® Drive.

Features

Features

- Non-symmetrical, elliptically-based geometric configuration

- Five lobes with a solid post in the center of the recess

- Drivers only available to OEMs and authorized service personnel

- Concentricity and tight tolerances of tamper-resistant TORX PLUS® tools make them very difficult to counterfeit

Benefits

- Allows optimum torque transfer and increased driveability

Allows improved productivity on the assembly line

Allows improved productivity on the assembly line- Non-symmetrical shape provides increased resistance to tampering

- Limited access to proper drivers maintains the integrity of the system

Standard Design Guidelines

Fastener Sizes:

M2.5 to M18 (#3 to 3/4")

Head Design:

A countersunk or button-head design is recommended.

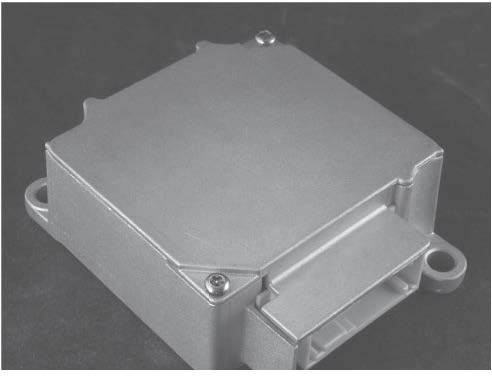

IMPROVES ASSEMBLY AND PROTECTS SYSTEMS

A manufacturer of power systems for electric vehicles needed a tamper-resistant fastener on the component's exterior to keep consumers away from its dangerous electrical currents. In addition, using hex and Phillips systems inside the component created debris from earnout that could short-circuit the system. These drive systems also could not provide enough torque to seat the fasteners properly. The loose fasteners created arcing, which would destroy the power supply. Switching to the tamper-resistant TORX PLUS® Drive System eliminated earnout and its resulting particulate matter and increased the torque that could be applied. It also prevents consumers from opening the component and possibly injuring themselves.

A manufacturer of power systems for electric vehicles needed a tamper-resistant fastener on the component's exterior to keep consumers away from its dangerous electrical currents. In addition, using hex and Phillips systems inside the component created debris from earnout that could short-circuit the system. These drive systems also could not provide enough torque to seat the fasteners properly. The loose fasteners created arcing, which would destroy the power supply. Switching to the tamper-resistant TORX PLUS® Drive System eliminated earnout and its resulting particulate matter and increased the torque that could be applied. It also prevents consumers from opening the component and possibly injuring themselves.