Fasteners for Thin Sheet Metal

Benefits

Works in thin sheet metal

Produces a sizable extrusion

Produces stronger female nut member

Increased clamp load

Serviceable for repeat assembly with metric machine screw

High strip out resistance

Uniform tightening torque in different material thicknesses

Features

Circular full body

45° thread angle

Reverse 45° thread in forming taper

Non-circular thread forming taper

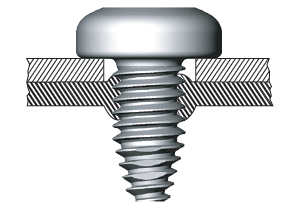

Today’s manufacturing environment continues to explore ways to use thinner sheet metal to reduce cost and weight. As material thicknesses decrease, fastening can become more problematic. SHEETtracs® is a self-tapping screw designed to be used in a pre-formed hole that produces assembly-safe metal joining.

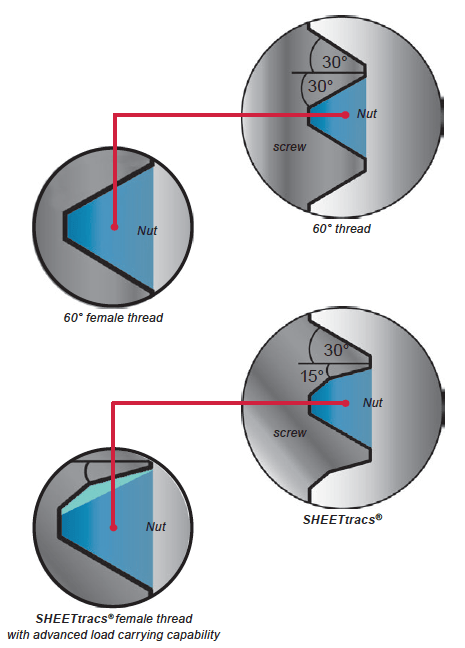

SHEETtracs® fasteners use a compound-angled metric machine screw thread pitch to engage into sheet metal. The thinner asymmetric 45° thread flanks displace less material than common 60° threads, resulting in stronger female threads and increased thread engagement.

The reverse flank angle in the thread-forming zone is designed to maximize the formed extrusion height. The thread-forming zone only affects the lead threads of the screw and ends before reaching the full body diameter of the thread.

The non-circular thread-forming zone enables simple concentric screw installation while minimizing thread-forming torque.

A large clean extrusion is formed, allowing the circular screw body to resist against low strip torque, achieve higher clamp load, and provide a uniform tightening torque.

The solid full-body thread engagement elevates vibration resistance. Multiple reinsertions are achievable in applications requiring serviceability.

Additional Family Products