Screw with Integrated Spring Element

Spring / Compression washer alternative

High clamp-load retention after thermal and dynamic loads

Built-in clamp-load sensor

Permanent electrical contact

Single piece cold headed fastener

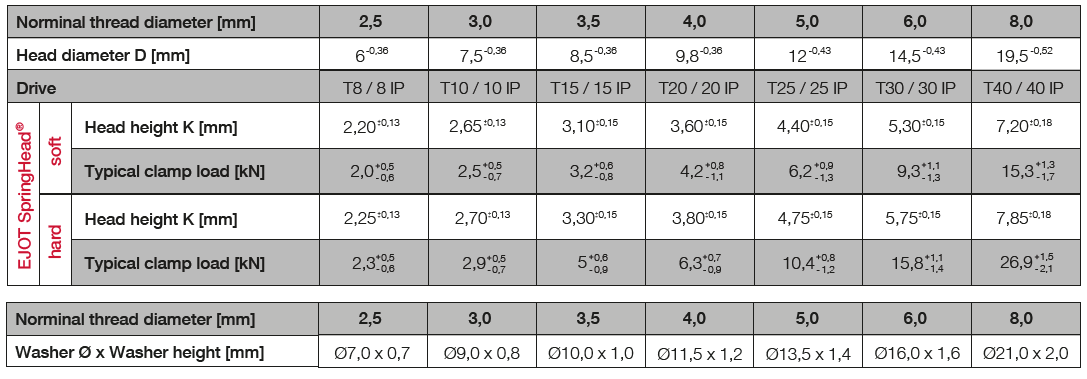

Two variations - for hard metal surfaces and softer surfaces such as plastic or copper

Pre-calculated typical clamp load ranges

Every screw connection loses clamp load after assembly due to subsidence. Dynamic and/or thermal stress intensifies this process.

If the clamp load falls below a critical level, the connection fails, for example, through loosening, separation, or a loss of electric contact. These failures can be prevented by increasing the elasticity of the screw connection. Amongst others, this can be achieved if spring elements are integrated into the screw connection. The innovative SpringHead geometry facilitates this resilient feature and reliably compensates for subsidence without additional conventional spring elements such as conical spring washers. The result is a screw head with an integrated spring for better clamp load retention under dynamic and thermal stress as well as permanent electrical contact.

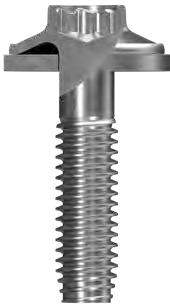

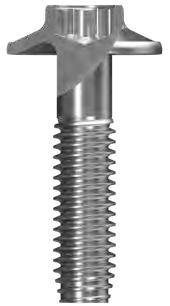

For clamping parts with a low admissible surface pressure (e.g., plastics or copper), an additional captive washer is recommended for better load distribution.

With Washer

Without Washer

The usage of combination screws with galvanic coatings in conjunction with high-strength self-tapping screws always bears the risk that the spring element might fail due to hydrogen embrittlement. The reason is that captive spring elements are assembled before heat treatment and galvanic coating. Especially during the coating process, the high-strength spring material is exposed to a possibly hypercritical hydrogen charge due to the necessary preparation processes.

Since the materials for screws and spring elements differ, the strength properties of the screw and a low susceptibility to embrittlement of the spring element cannot be guaranteed at the same time.