Newest Generation Thread Rolling Screw

Benefits

Preferable Failure Mode - when the screw is overtightened in standard lengths of engagement, the screw will fracture within the screw threads

High Prevailing Torque - provided by the TRILOBULAR® shape

Deep Thread Engagements - generates strong mating threads with uninterrupted grain flow

Features

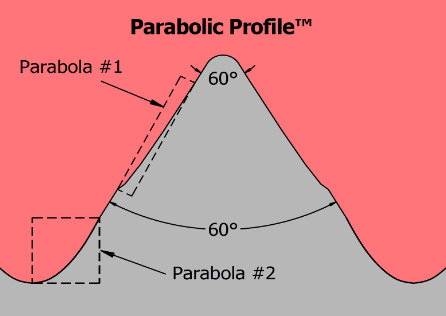

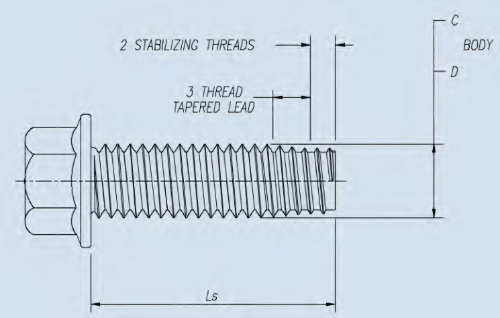

Innovative Parabolic Profile™ Thread

Threads formed by TAPTITE PRO® will accept standard machine screws

Sharp tapered lead threads

Increased TRILOBULAR® shape on taper of larger sizes

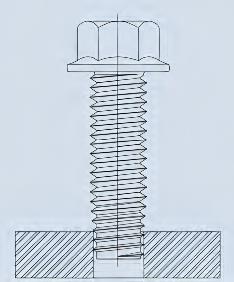

TAPTITE® PRO™ thread-forming fasteners, the next evolution of TAPTITE® fasteners, advances current thread-forming technology with the development of the Parabolic Profile™ thread form. The innovative new thread form, combined with the proven TRILOBULAR® cross-section, provides low thread-forming torque, excellent resistance to vibrational loosening, high axial pull-out, and reduced overall assembly cost. In addition to these great benefits, TAPTITE® PRO™ fasteners maintain torque tension relationships comparable to machine screws of equivalent size, as well as an improved failure mode; as a result of overtightening in standard lengths of engagement, the screw will fracture within the screw threads.

This preferred failure mode greatly reduces the risk of costly assembly line repairs and scrap due to stripped nut members or castings and the associated waste due to line downtime. This important design improvement is effective in steel and soft white metal applications, ensuring continued savings on the Big 85™ in a wide range of your current and future fastened joints.

Advantages of using TAPTITE PRO® Technology

- Preferable Failure Mode - when the screw is overtightened, in standard lengths of engagement, the screw will fracture within the screw threads

- Eases Assembly - low-end load to initiate thread-forming, less operator fatigue

- Low Thread Forming Torque - increased out of round point threads

- Speeds up Assembly - no assembly line cross-threading

- Superior Vibration Resistance - eliminates the need for add-on locking devices

- High Prevailing Torque - provided by the TRILOBULAR® shape

- Deep Thread Engagements - generates strong mating threads with uninterrupted grain flow

- High Axial Pull-Out Loads - similar to that achieved using machine screws and bolts

- Various Metals & Hole Types - works in punched, drilled, cored and extruded holes

- No Secondary Clean-Up - forms threads in nut members contaminated with paint, primer, or weld

- splatter

- Support - provided by REMINC/CONTI and fastener supplier personnel worldwide

- Availability - procurement available around the world

- Quality - official fasteners manufactured to strict standards

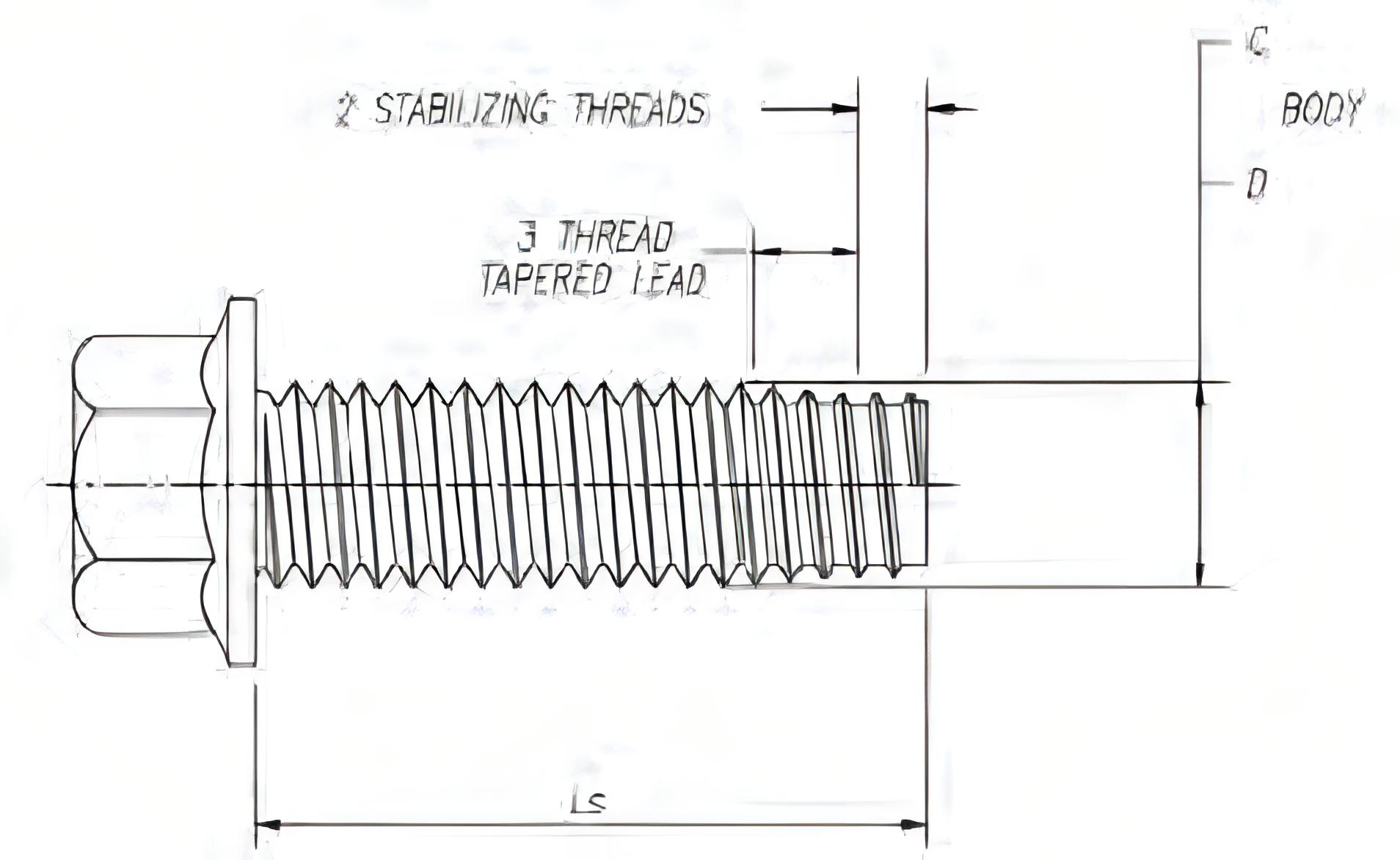

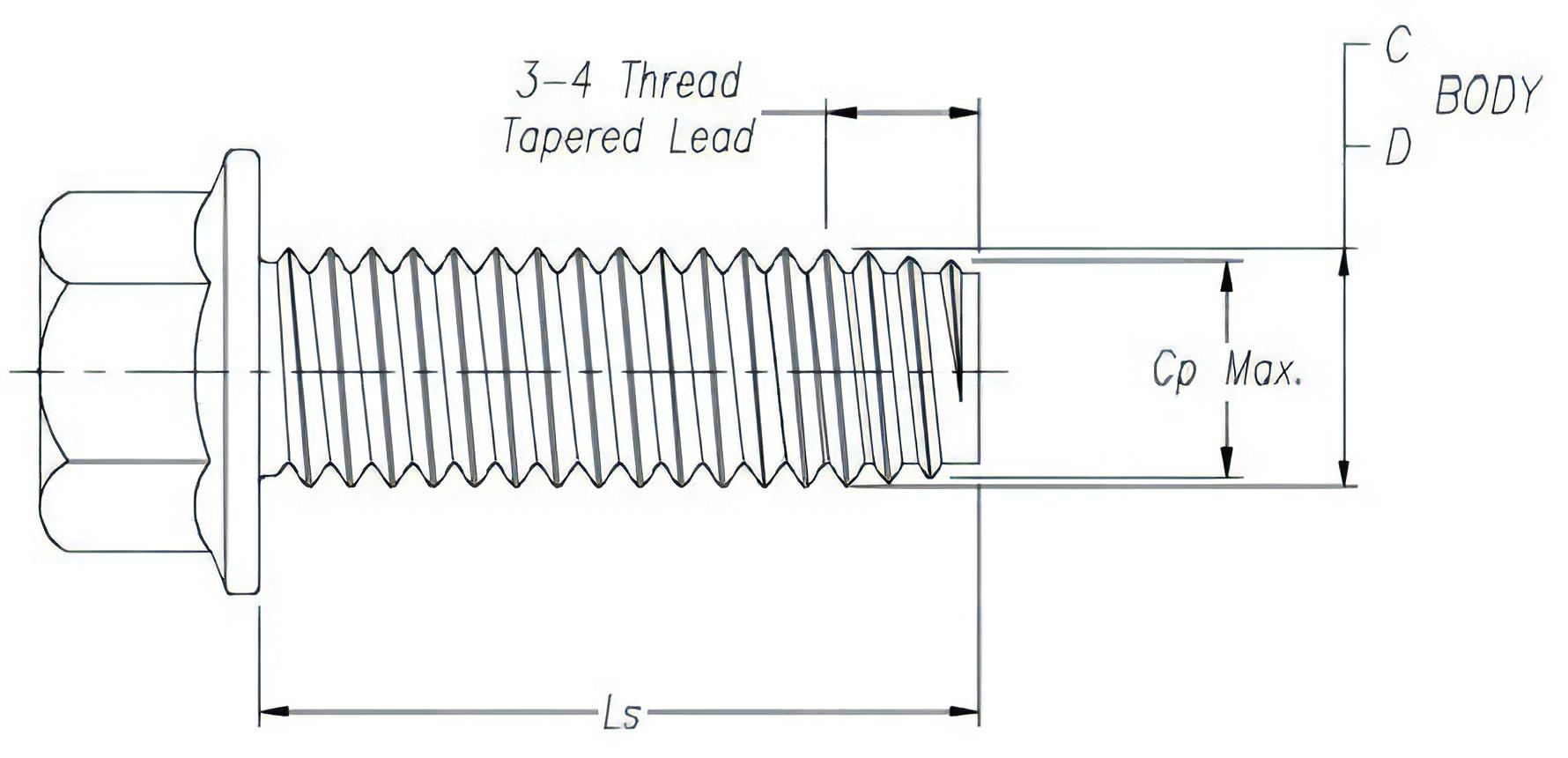

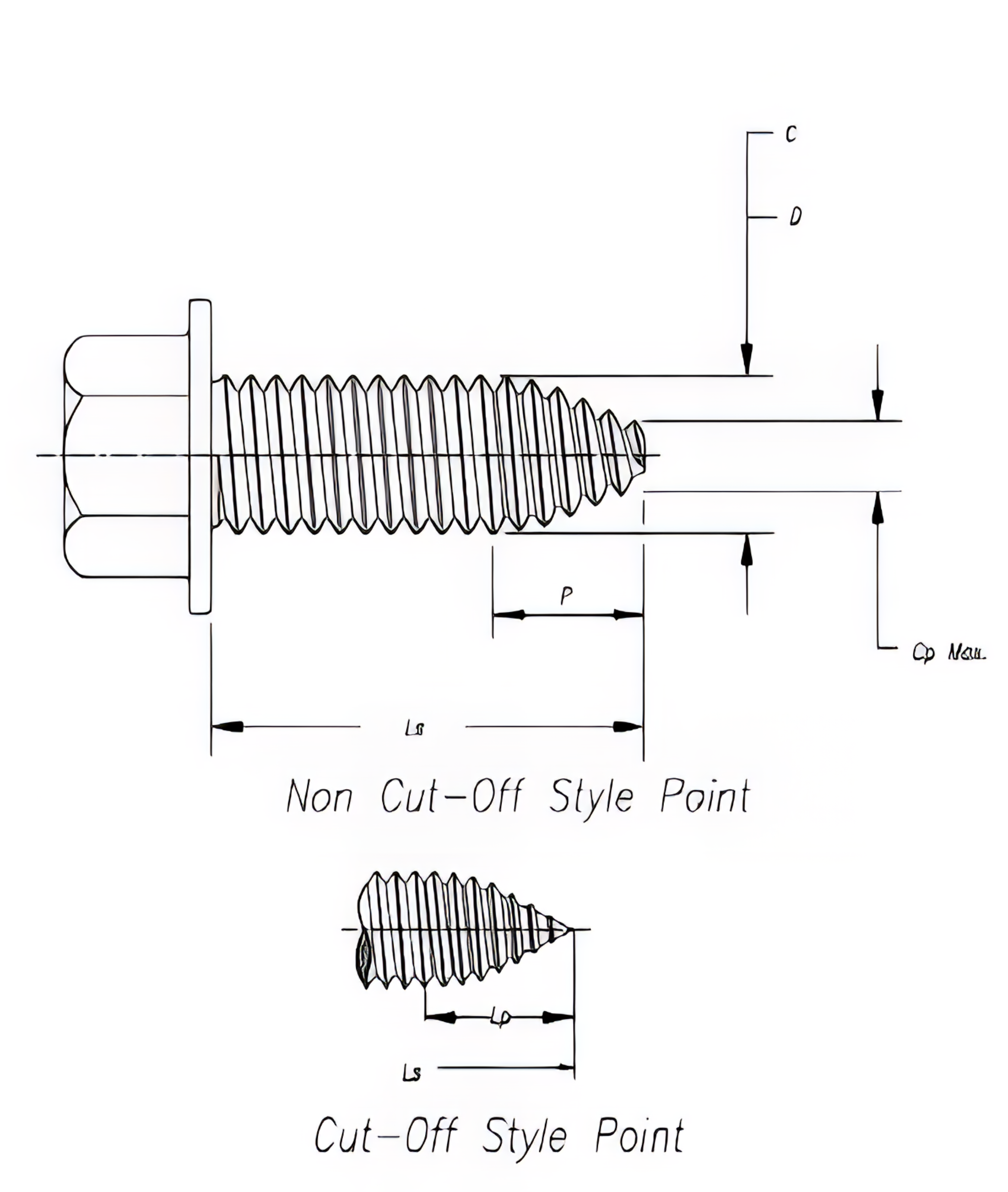

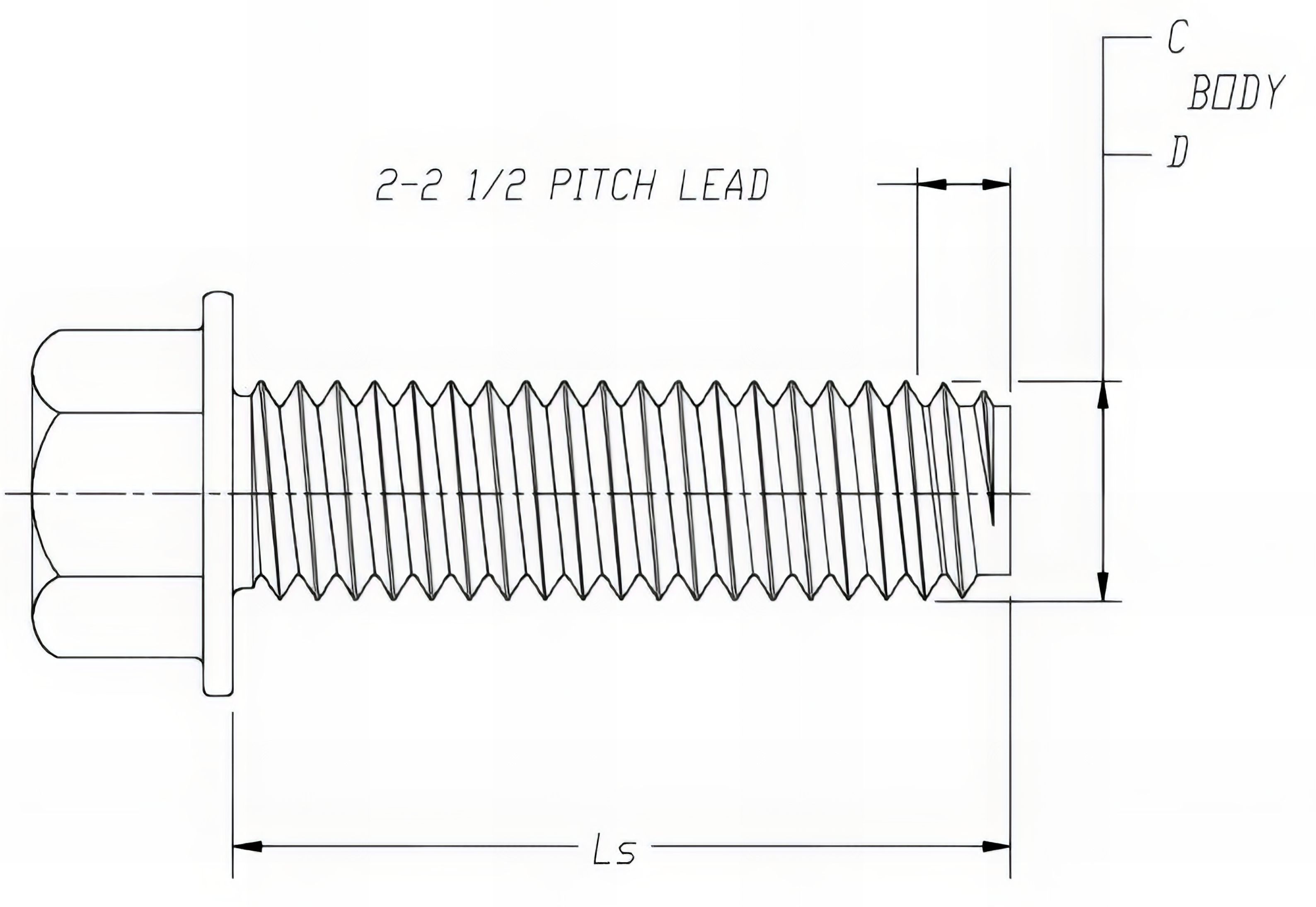

TAPTITE PRO® Designs

TAPTITE PRO® bolts

M6 (1/4 - 20) & above

TAPTITE PRO® screws

M5 (12 - 224) & below

TAPTITE® PRO™ “CA”™ screws & bolts Rapid Hole Finding, Floating Nut Members & Difficult to Access Applications

TAPTITE® PRO™ “SP”™ screws & bolts For Use in Aluminum & Zinc Die Castings

TAPTITE® PRO™ Fasteners Reduce the Cost of Assembly

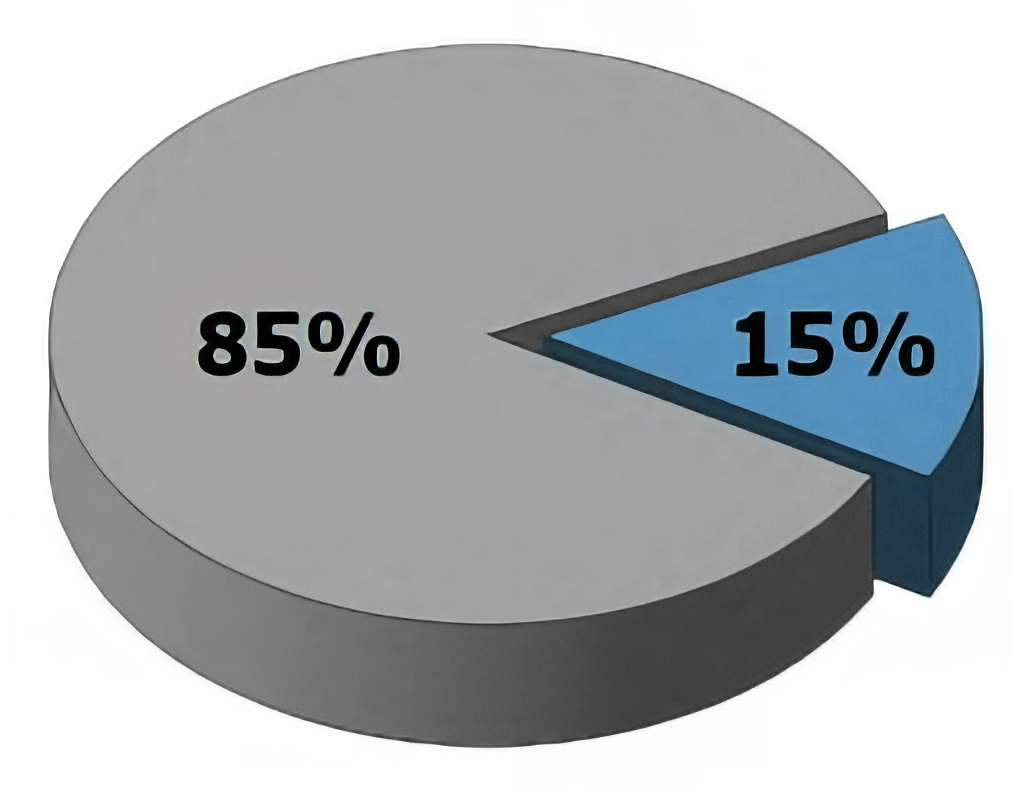

When installing a simple screw, most of the assembly cost is composed of preparing the hole, tapping, cleaning, applying the locking compound, driving the screw, operator cost, etc. These elements make up what we call the “Big 85™”. The actual fastener makes up only 15% of assembly costs.

A fastener, which reduces the “Big 85™” will considerably lower assembly costs than buying a cheaper fastener.

The TAPTITE® thread rolling screw family has been reducing the “Big 85™” in automotive, white goods, lawn equipment, and electronics for decades. From a history of use beginning with the 1964 Ford Mustang to the latest cell phone, one major idea has been constant with TAPTITE® products - “In-Place Cost Savings”.

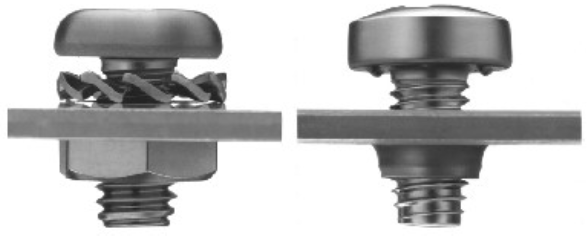

TAPTITE® PRO™ screws eliminate the costs of tapping, washers and locking compounds, or even the use of a nut. To find out how TAPTITE® PRO™ thread rolling screws can save on your assembly costs, contact our application engineers or any of our highly-qualified licensed manufacturers listed on www.taptite.com.

Standard Fastener Installation components

Standard Fastener Installation components

- Labor

- Overhead

- Preparation of assembly

- Drilling and tapping the hole

- Application of Locking device or adhesive

- Driving and tightening the screw

These costs make up the BIG 85™

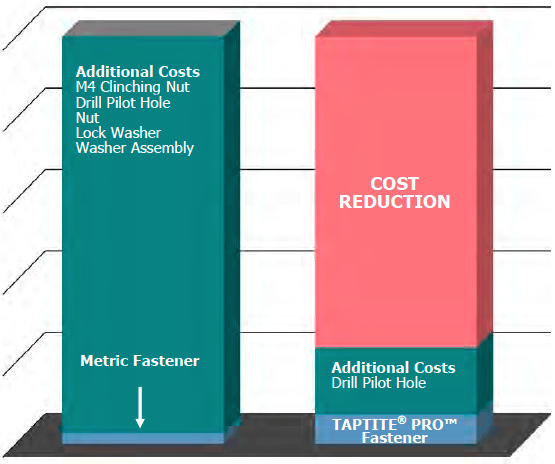

Joint Costs: Lighting Appliance

3 Fastening elements

2 assembly directions

Manual assembly (complex)

2 assembly processes

1 fastening element

1 assembly direction

Automated assembly

1 assembly process

Standard Screw

|

TAPTITE® PRO™

|

|

|---|---|---|

|

Screw M4 x 8 |

1.5 |

3.39 |

|

Chincing Process |

9.07 |

--- |

|

Drill/Punch Pilot Hole |

12.73 |

12.73 |

|

Cinch Nut |

14.57 |

--- |

|

Lock Washer |

.87 |

--- |

|

Washer Assembly |

3.64 |

--- |

|

Total |

42.00 |

16.12 |

|

SAVINGS |

61% |

|

Typical TAPTITE® Product Applications

|

APPLICATION |

“Hatch-Back” Strut |

|

FASTENER > |

M6 TAPTITE® bolt with shoulder |

|

PROBLEM |

Limited access prevented repair nut replacement |

|

BENEFIT |

Eliminated need for nut & consequential repair costs |

|

APPLICATION |

Mounting Amplifier to Carrier Frame |

|

FASTENER |

TAPTITE® screw w/ captive isolation washer |

|

PROBLEM: |

Vibrational loosening |

|

BENEFIT |

Excellent fastening values & high process capability |

|

APPLICATION |

Seat Belt Bolts, Front and Shoulder Harness |

|

FASTENER |

M12 x 35mm TAPTITE® screws |

|

PROBLEM |

Cross threading during assembly |

|

BENEFIT |

Eliminates tapping operation |

|

APPLICATION |

TAPTITE® Screws Used to Assemble Aluminum Power Transfer Unit |

|---|---|

|

FASTENER |

M8 x 1.25 x 35 hex flange head TAPTITE® screws |

|

PROBLEM |

Expensive secondary tapping operation |

|

BENEFIT |

Elimination of all tapping associated costs |

Additional Family Products