Optimized Thread Forming Fastener for High-Strength Steels

Ability to form threads in high-strength steels

High stripping torque typical of round body fasteners

Low thread forming torque due to proprietary Rolok® feature

Reduced required end load for improved assembly ergonomics

Increased torsional strength for thread forming in thick steel materials

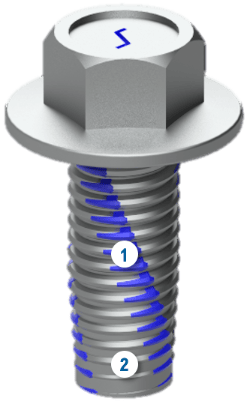

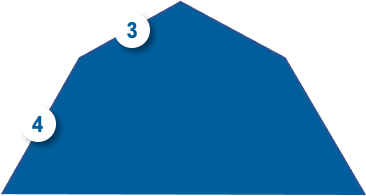

Large upper flank angle changes thread loading from shear to compression eliminating thread collapse

Proprietary torque reducing Rolok® feature innovatively adapted for high-strength steels

Formed threads will accept standard machine screws

Round body allows for thread rolling into asymmetrical holes

Available in short point configurations

What screws are used in High-Strength Steel (HSS) and Advanced High-Strength Steel (AHSS)?

Rolok® HS® Rolok HS utilizes an innovative thread design capable of forming threads upwards of 1200 MPa tensile strength into steels.

Is a small sample of screws available for testing in High-Strength Steel (HSS) and Advanced High-Strength Steel (AHSS)

Semblex offers Rolok® HS® screws for testing purposes with metric sizes ranging from M4-M10, with others available upon request.

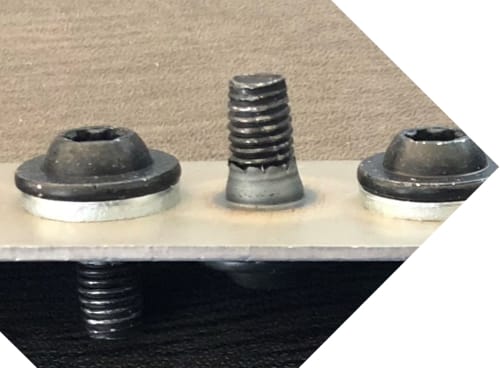

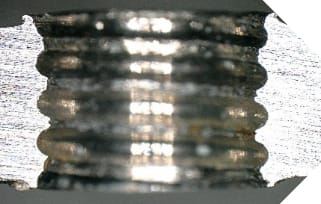

Semblex’s innovative Rolok HS® design has been specifically developed for the joining of high-strength steels. Its unique compound thread angle provides exceptional assembly performance while overcoming thread damage and collapse that plague traditional thread rolling screws.

A large upper flank angle increases compressive strength and reduces shear loading, preventing thread collapse.

A large upper flank angle increases compressive strength and reduces shear loading, preventing thread collapse.

Rolok HS® hole sizing is application-dependent; please contact Semblex Engineering Services for details.

|

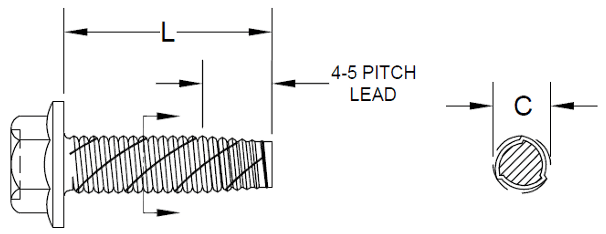

Screw Length (L) |

Tolerance |

|

Up to 20mm |

+0.0/-0.8 mm |

|

Over 20mm to 40mm |

+0.0/-1.3 mm |

|

Over 40mm |

+0.0/-1.5 mm |

|

Screw |

Circumscribing Diameter (C) |

|

|

Max |

Min |

|

|

M4-0.7 |

4.09 |

3.93 |

|

M5-0.8 |

5.09 |

4.94 |

|

M6-1.0 |

6.10 |

5.95 |

|

M8-1.25 |

8.13 |

7.98 |

|

M10-1.5 |

10.15 |

9.98 |

HEAT TREATMENT

HEAT TREATMENT Case hardening is considered for non-safety critical applications when the mating material is 800 MPa tensile strength or less. All other applications should utilize hardening with induction-hardened lead threads.

FINISH

Various coating and plating options are available to meet specific customer requirements for corrosion and joint performance.

Fasteners:

Heat Treat:

Hole Diameter:

Speed:

Number of Tests:

M5-0.8 X 12mm

Induction Hardened

4.60, 4.65, 4.70mm

225 RPM

90 Per Fastener

30 Per Hole Dia.

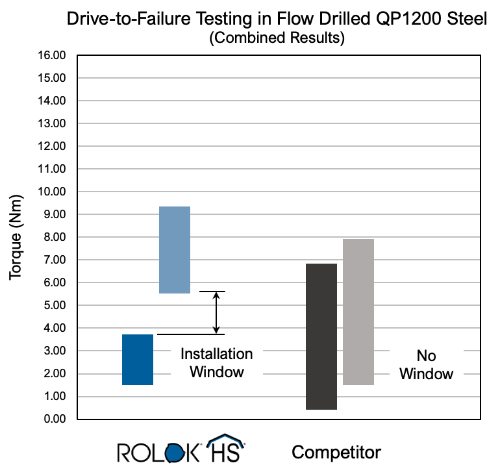

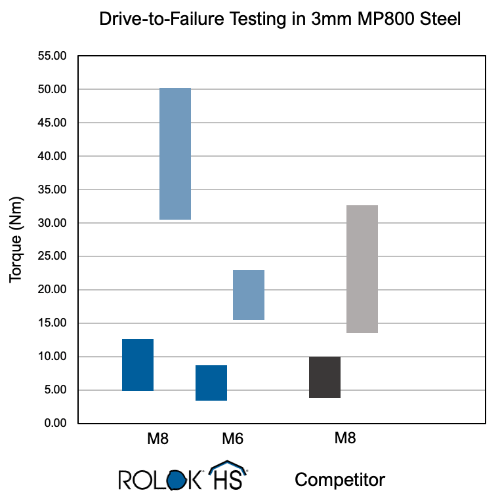

Fasteners:

Heat Treat:

Hole Diameter:

Speed:

Number of Tests:

M8-1.25 X 30mm

M6-1.0 X 20mm

Induction Hardened

RHS M8: 7.40, 7.60mm

RHS M6: 5.55, 5.69mm

Comp M8: 7.30, 7.50mm

150 RPM

60 Per Fastener

30 Per Hole Dia.

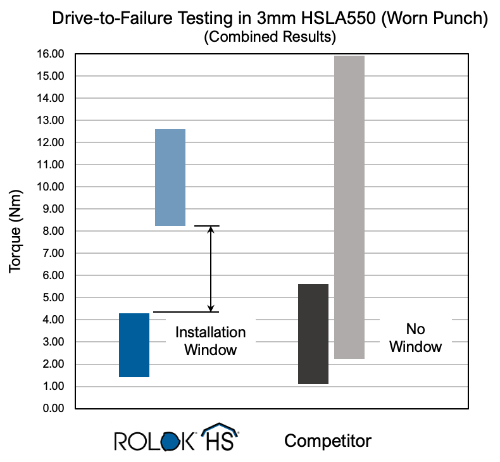

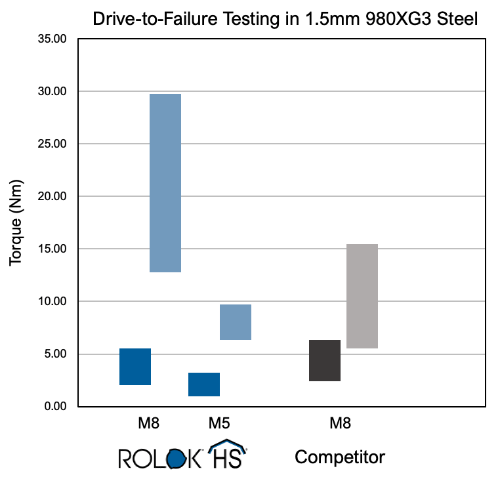

Fasteners:

Heat Treat:

Hole Diameter:

Speed:

Number of Tests:

M8-1.25 X 30mm

M5-0.8 X 12mm

Induction Hardened

RHS M8: 7.40, 7.60mm

RHS M5: 4.53, 4.67mm

Comp M8: 7.30, 7.50mm

225 RPM

60 Per Fastener

30 Per Hole Dia.

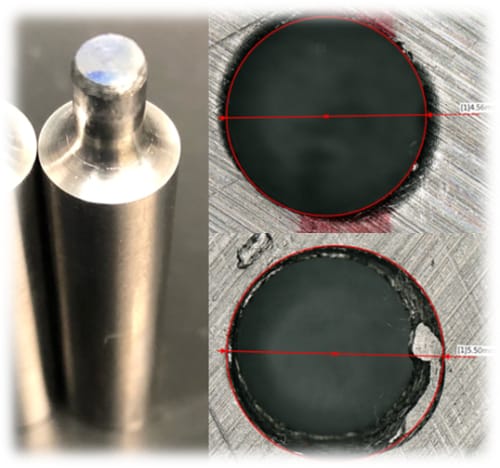

Image of worn punch and resultant holes used for testing.

Fasteners:

Heat Treat:

Hole Diameter:

Speed:

Number of Tests:

M5-0.8 X 12mm

Case Hardened

4.53, 4.60, 4.67mm

225 RPM

90 Per Fastener

30 Per Hole Dia.