Enhanced Productivity and Tool Life

Benefits

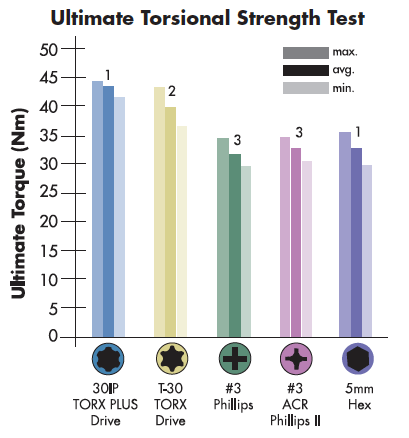

100% average improvement in driver bit life over Torx®

25% average improvement in driver bit torsional strength

Compatible with existing Torx® bits

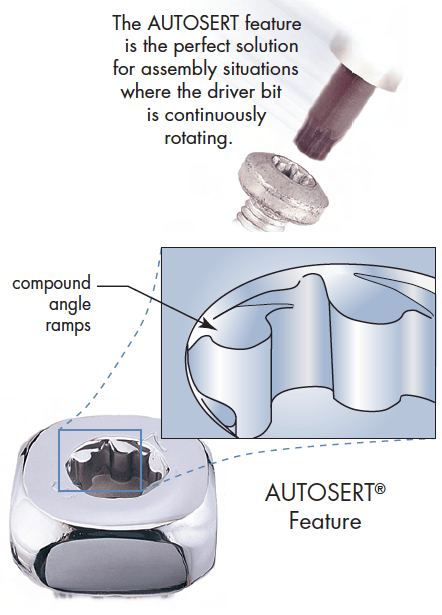

Torx Plus® with Autosert® allows for drive bit insertion while turning, increasing productivity and cycle time.

Features

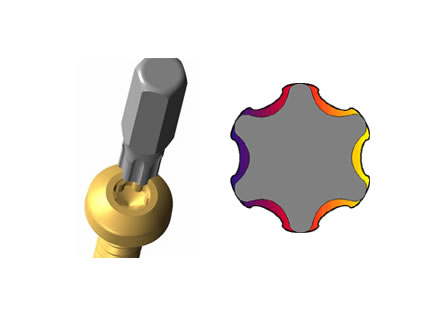

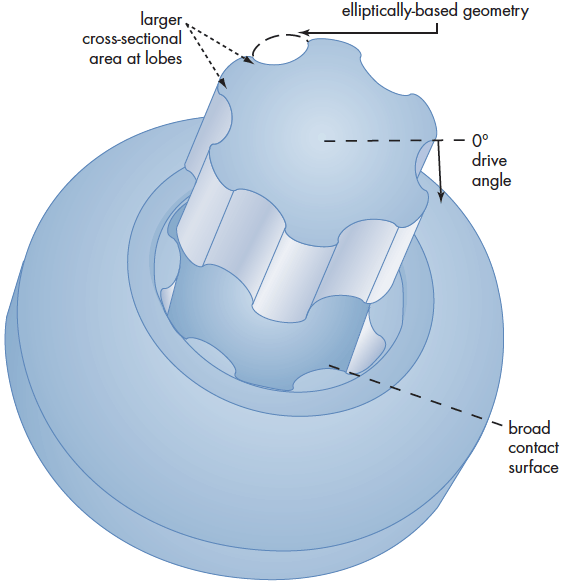

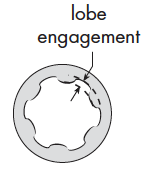

Elliptically based geometry provides increased contact area on lobes

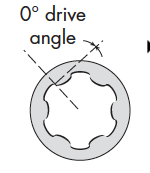

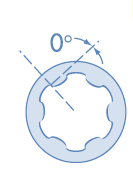

0° drive angle

Driver tool tolerance reduced by 50% resulting in improved tool/recess fit as compared to Torx®

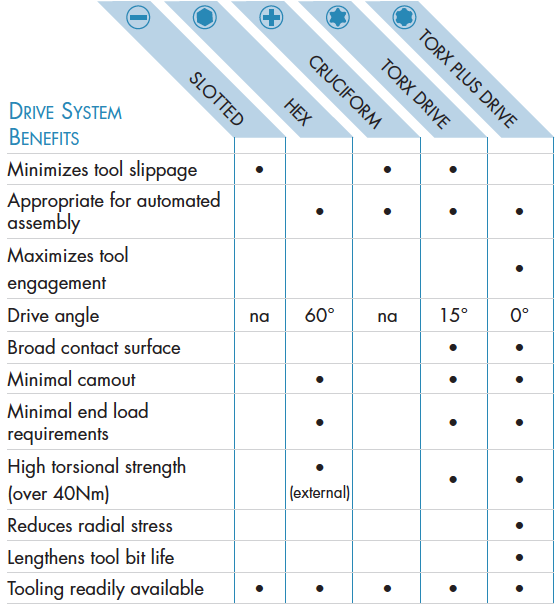

How Important Is Your Drive System?

The fasteners you use in your product may seem insignificant, but they are important to your overall productivity, quality, and profitability. The drive system on those fasteners affects assembly speed, downtime, worker comfort, and the amount of reworked and/or scrapped components, as well as product design.

Why Other Drive Systems Cause Problems on the Assembly Line

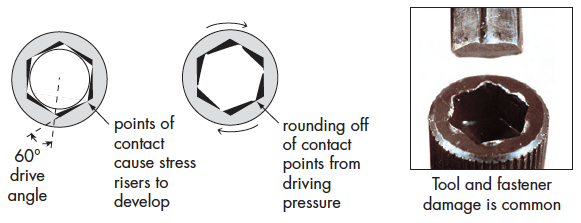

HEX

HEX

- point contact causes stress risers to develop, which damages the driver bit and fastener recess

- A 60° drive angle is inefficient in transferring torque

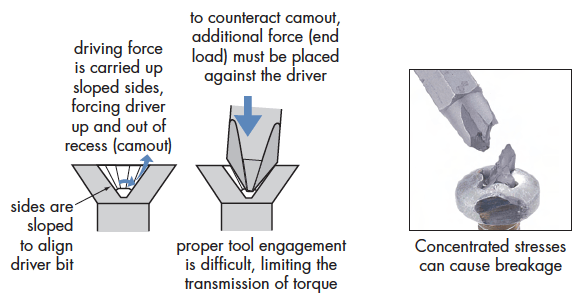

Cruciform

Cruciform

- Camout, which forces the drive tool out of the recess, is a common

- Camout and its limits on torque transfer can prevent a fastener from being fully seated

- Excessive end-load, required to prevent cam-out, can reduce bit life and cause worker fatigue or injury

- Camout and tool/recess wear can create debris in an application

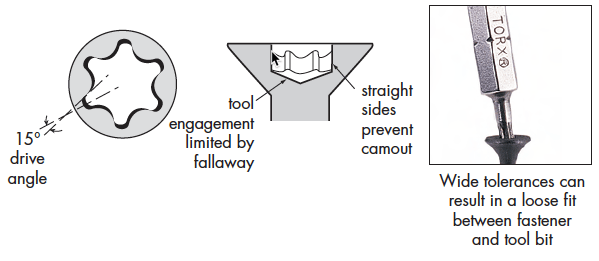

TORX® Drive

TORX® Drive

- Allows higher torque transmission

- A 15° drive angle still permits a small amount of radial stress, which can reduce bit life

- Tool may be difficult to align properly in high-speed assemblies

The Solution to Your Assembly Problems

Since its introduction, TORX PLUS® Drive has consistently outperformed every other drive system. Its longer tool life and optimal torque transfer have enhanced product reliability, increased productivity, and reduced total assembly costs on assembly lines in a multitude of industries around the world.

Inch & Metric In One Drive Tool

- Same-sized drive tool seats both inch and metric-sized fasteners

- Add or convert to metrics without a tooling change

- Reduce the number of tools required by field service personnel

Compatible with TORX® Drive for Field Service

- TORX Drive tools can be used to remove and reinstall TORX PLUS Drive recess fasteners

Elliptically-based Geometry

- Broadens contact surface to maximize engagement of driver and recess.

- Eliminates damaging point-to-point contact

0° Drive Angle

- Optimizes torque transmission

- Virtually eliminates radial stresses to increase tool bit life

- Allows use of thinner-walled recesses

Six Lobes With Large Cross-Sectional Areas

- Allows faster tool engagement

- Maximizes torque transfer

- Increases torsional strength

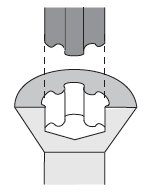

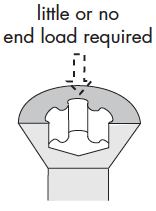

Vertical Sidewalls & Reduced Recess Fallaway

- Increases tool engagement

- Virtually eliminates camout

- Ensures proper torque transfer

- Greatly reduces end-load requirements

- Minimizes tool slippage and damage it can cause

- Can reduce fatigue and muscular stress during manual assembly of fasteners

Greatly Increased Strength and Reliability

- 100% average improvement in driver bit life; many users of the TORX PLUS Drive System have driven 2 to 10 times more fasteners per drive tool

- 25% average improvement in driver bit torsional strength

- Increased bit strength allows for higher removal torque capability

TORX PLUS® Drive Solves Assembly Problems

You may have come to accept frequent tool bit changes, camout, damaged components, and slowed assembly lines as a cost of using fasteners in your product. But it doesn’t have to be that way.

The TORX PLUS® Drive was designed to enhance assembly line performance. Manufacturers worldwide have realized significant improvements and cost savings by switching to the TORX PLUS Drive.

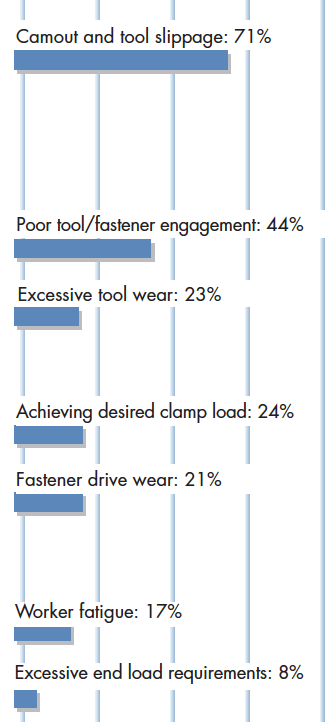

Most Common Fastener Driving Problems*

*Results of a Design News/Cahners Research study on fastener drive styles, published March 1998. Respondents were design engineers involved in product or system design

TORX PLUS® Drive SOLUTIONS

The straight, vertical sidewalls of the TORX PLUS Drive System virtually eliminate camout. Also, the TORX PLUS recess completely encloses the driver tip, reducing tool slippage and costly and unsightly damage to the fastener and surrounding surfaces.

The elliptically-based geometric configuration of the TORX PLUS Drive System maximizes engagement between driver and fastener. It spreads driving forces over the surface area, extending tool life.

The elliptically-based geometric configuration of the TORX PLUS Drive System maximizes engagement between driver and fastener. It spreads driving forces over the surface area, extending tool life.

TORX PLUS Drive is the only drive system designed to ensure optimum torque transmission and, ultimately, required clamp load. With a true 0° drive angle, the TORX PLUS system virtually eliminates the radial forces that can cause stress on fastener recesses.

TORX PLUS Drive is the only drive system designed to ensure optimum torque transmission and, ultimately, required clamp load. With a true 0° drive angle, the TORX PLUS system virtually eliminates the radial forces that can cause stress on fastener recesses.

Ergonomic studies demonstrate that the TORX PLUS Drive System can reduce fatigue and muscular stress during the manual assembly of fasteners. That’s because little or no end load is required to keep the driver engaged in the recess.

Ergonomic studies demonstrate that the TORX PLUS Drive System can reduce fatigue and muscular stress during the manual assembly of fasteners. That’s because little or no end load is required to keep the driver engaged in the recess.

Perfect for High-Speed Assembly Lines

Reducing Installation Time & Drive Bit Usage

Application: Truck trailer floor

Fastener Description: 5/16-18 Taptite® thread-forming screw

Assembly Method: Manual stand-up, two-hand drive gun whose bit continuously spins at 2,200 rpm

Assembly Problem: When using TORX Drive, the assembly line had to be slowed down to ensure proper drive bit/recess engagement.

TORX PLUS Drive Solution: TORX PLUS Drive with AUTOSERT feature allows the drive bit to remain at full speed when engaging the fastener, increasing productivity.

Customer Benefits:

Customer Benefits:

- Installation time was reduced by as much as 20 minutes per trailer

- Drive bit usage was reduced from 45 bits per week to less than 5 per week

Difficulty in aligning the drive bit and the recess can force an assembly line to slow down to ensure proper fastening.

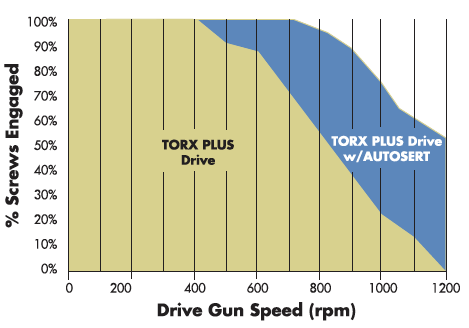

AUTOSERT® Feature: The High Productivity Answer to High RPM Engagement

The compound angle ramps of the AUTOSERT feature guide the driver bit into the recess, creating a self-centering and engaging action. It’s the perfect solution for automated, robotic, and other assembly situations where the driver bit continuously rotates.

- Allows for higher rpm engagement

- Speeds engagement

- Reduces assembly time

- Increases productivity

An enlarged window of engagement improves drive bit alignment in offset and off-angle conditions

- Eases starting

- Eliminates the need to slow down the driver bit

Lobe Engagement

- Increases tool life – during beta site testing, a manufacturer achieved reduced drive bit usage at over 1500 rpm

- Eliminates camout debris

This patented feature is a TORX PLUS Drive exclusive, available in drive sizes 6IP – 100IP.

Laboratory testing reveals 100% of recesses.

Using the AUTOSERT feature, we were engaged with TORX PLUS Drive bits rotating at 700 rpm.

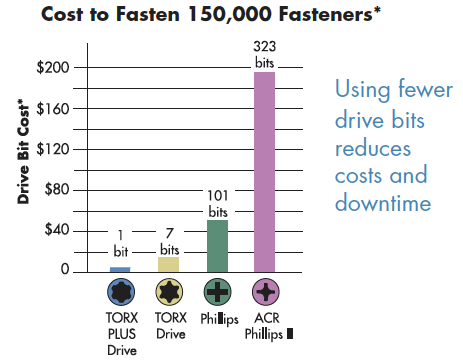

TORX PLUS® Drive Lowers In-Place Costs

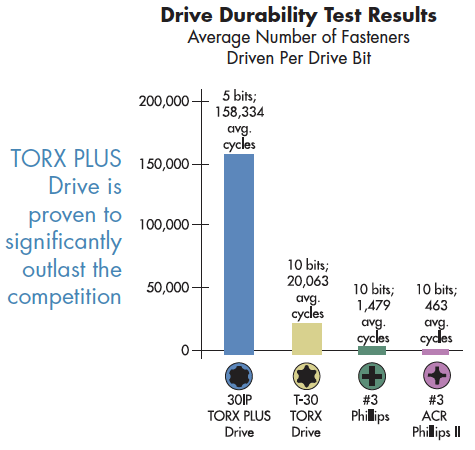

Longest Tool Bit Life Available

The elliptically-based geometry of the TORX PLUS Drive system maximizes lobe engagement between driver and fastener, spreading driving forces over its surface area. This extends tool life and maximizes torque transfer.

In test after test, on assembly line after assembly line, the TORX PLUS Drive has been proven to significantly outlast all other drive systems.

Reduces Assembly Line Downtime

One of the most overlooked assembly line costs is downtime. Every time a fastener drive bit fails, the line has to be shut down to change the bit. Over time, line downtime can significantly negatively impact productivity and profitability.

Many customers who have switched to the TORX PLUS Drive report driving 2 to 10 times more fasteners per bit.

Reduces Annual Drive Tool Costs

Although a single TORX PLUS Drive bit or socket may cost more than competing systems, its longer life translates into more assemblies per bit and significantly lower overall tooling costs.

*The costs above reflect the number of bits each system would need under the conditions of the Drive Durability Test described above.

Drive Bit Costs Reduced By $15,000 Annually.

Application: Automotive air suspension system Assembly Method: Automated assembly line utilizing a 4-position, multi-spindle driving station to drive Plastite® fasteners.

Assembly Problem: The customer replaced their four Phillips drive bits three to six times daily over three shifts. This resulted in assembly line downtime and the costs of replacing 12 to 24 bits per day.

TORX PLUS Drive Solution: The first TORX PLUS bits were replaced after four months of use and then only as a precautionary measure. The customer noted that the bits were hardly worn and could have lasted much longer.

Customer Benefits:

Customer Benefits:

- Lowered drive tool costs by $15,000 annually

- Reduced assembly line downtime due to fewer drive bit changes

- Improved productivity

TORX PLUS® Drive Benefits Product Quality

TORX PLUS® Drive Benefits Product Quality

Achieves Proper Clamp Load

If the proper clamp load isn’t reached or camout forces a driver out of the recess before it is fully seated, the fastened joint can easily loosen. This can lead to leaks, squeaks, rattles, or even complete joint failure, which may require service in the field and result in higher warranty rates.

TORX PLUS Drive is the only drive system designed to ensure optimum torque transmission and, ultimately, required clamp load.

Minimizes Rework

Poor torque transfer due to drive bit wear can result in a poorly built component that needs to be disassembled, reworked, and reassembled, which adds labor and material costs. Scrapped rejects — components that cannot be reworked — represent wasted costs.

The longer bit life of the TORX PLUS Drive helps ensure that proper torque transmission occurs consistently.

Prevents Damage to Application

Prevents Damage to Application

If tool slippage or camout forces the driver out and across a component, damage to the surrounding surfaces, such as scratches and dents, can occur. TORX PLUS Drive recesses completely enclose the driver tip, preventing tool slippage. That design feature and minimal camout means the TORX PLUS Drive bit will stay where it belongs, preventing damage to itself, the fastener recess, and the application.

Camout and tool/recess wear can also create damaging debris. This diminishes the aesthetic value of the fastener and, more importantly, can cause irreparable damage to electronic assemblies, airbags, and other critical applications.

Camout and tool/recess wear can also create damaging debris. This diminishes the aesthetic value of the fastener and, more importantly, can cause irreparable damage to electronic assemblies, airbags, and other critical applications.

The longer life of the TORX PLUS Drive minimizes tool and fastener wear, and its straight sidewalls virtually eliminate camout. That makes the TORX PLUS Drive the optimal drive system for every application.

Reduces Worker Fatigue and Muscular Stress

Reduces Worker Fatigue and Muscular Stress

Workers can experience fatigue and muscular stress during the manual assembly of cruciform or slot drive fasteners caused by the pressure they must exert to keep the driver engaged in the recess (end load). This can lead to reduced productivity or even injuries.

Ergonomic studies demonstrate that the TORX PLUS Drive System can reduce fatigue and muscular stress during the manual assembly of fasteners. That’s because little or no end load is required to keep the driver engaged in the recess.

TORX PLUS® Drive Ensures Optimal Torque Transfer

Designed for High Torque Transmission

Unlike the inefficient designs of other systems, TORX PLUS Drive is the only drive system designed to ensure optimal torque transmission. With a true 0° drive angle, the TORX PLUS system virtually eliminates the radial forces that can cause stress on fastener recesses.

TORX PLUS Drive's high torque transfer capabilities mean it can utilize increased seating torques without increasing current bit usage.

High torque transfer capabilities are also important when removing a fastener in service environments, where corrosion can cause seizing in the joint.

TORX PLUS Bit Strength

|

Drive |

Min. Torsional Strength |

|

|---|---|---|

|

Lbs./Inch |

Nm |

|

|

1IP |

0.96 |

0.11 |

|

2IP |

1.41 |

0.16 |

|

3IP |

2.50 |

0.28 |

|

4IP |

3.84 |

0.44 |

|

5IP |

5.37 |

0.61 |

|

6IP |

9.83 |

1.11 |

|

7IP |

18.60 |

2.10 |

|

8IP |

28.40 |

3.21 |

|

9IP |

37.10 |

4.19 |

|

10IP |

48.00 |

5.42 |

|

15IP |

85.10 |

9.62 |

|

20IP |

143.00 |

16.10 |

|

25IP |

208.00 |

23.50 |

|

27IP |

306.00 |

34.62 |

|

30IP |

418.00 |

47.20 |

|

40IP |

726.00 |

82.10 |

|

45IP |

1,216.00 |

137.40 |

|

50IP |

1,722.00 |

194.50 |

|

55IP |

3,116.00 |

352.10 |

|

60IP |

5,011.00 |

566.20 |

|

70IP |

8058.00 |

910.40 |

|

80IP |

11,422.00 |

1,290.50 |

|

90IP |

17,036.00 |

1,924.80 |

|

100IP |

23,412.00 |

2,645.20 |

In this test, the head of each fastener was held fixed, then driven until either the drive bit or the recess failed:

1– recess ream 2 – bit fracture 3 – camout

NOTE: M6 x 1.0, pan head, Class 10 fasteners driven at 8 rpm with 35.6 Newtons end load, at 0° off angle. The head was held fixed.

Productivity and Assembly Quality Improve

Application: Refrigeration compressors

Assembly Method: Automated assembly line Assembly Problem: An internal hex fastener was causing excessive line stoppage due to the number of drive bit changes – the manufacturer was able to fasten only 8,000 screws per hex bit. Also, many assemblies had to be rejected when the hex bits could not reach proper torque levels.

TORX PLUS Solution: With the TORX PLUS Drive System, the customer was able to fasten over 500,000 TORX PLUS fasteners with a single bit, and the proper torque levels were easily reached.

Customer Benefits:

Customer Benefits:

- Lower drive tool costs

- Fewer drive tool changes

- Improved productivity and reduced downtime

- Reduced rejected assemblies

- From 8,000 screws fastened per bit to over 500,000

TORX PLUS® Drive Surpasses the Competition

What is your most annoying fastening problem? Damaged applications? Constantly changing tool bits? Perhaps your current system solves one problem only to cause another.

Only the TORX PLUS Drive gives you all the benefits you need to have a more efficient, more productive assembly line.

Using TORX PLUS® Drive Benefits Your Entire Organization:

Using TORX PLUS® Drive Benefits Your Entire Organization:

Purchasing

- Reduced tooling costs

- Reduced overall costs

Manufacturing

- Reduced downtime from tooling changes

- More assemblies per shift

- Reduced worker fatigue

Quality Control

- Ensures proper seating of fasteners

- Reduced field service and warranty claims due to improperly seated fasteners

- Reduced number of scrapped or reworked components