Thread Forming Fastener for Magnesium

Minimizes debris generation

Forms strong threads in materials with low ductility

Can be easily removed and reinserted for service in the field

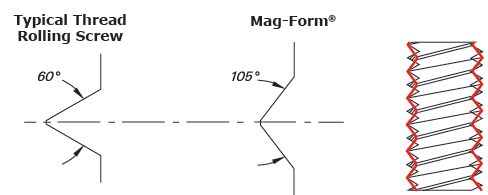

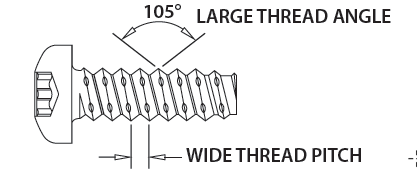

Unique 105° threads

Pentagonal body for lower installation torque

Compressive action forms strong threads in low-ductile material

Mag-Form® Fastener

Compressive action forms strong threads in the low-ductile material

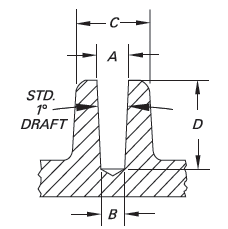

Standard 60° Flank Angle Thread Forming Fastener

May exceed ductility limit of the material, causing damage to formed threads

Sizes: MG1.6 to MG12

Sizes: MG1.6 to MG12

Thread Designs: Wide-spaced thread with a broad flank angle

Head Design: Can be used with any external or internal head designs

Drive System: can be used with all systems, including TORX PLUS® Drive

Finish: A wide variety of coating and plating options can be applied to Mag-Form® fasteners to meet specific customer requirements for corrosion resistance and joining performance

Automotive Powertrain & IP

Airbag assemblies

Mirrors

Pedal brackets

Steering components

Lawn and garden

Small engines

Power tools

Electronics

Cellphones

Computers

Mag-Form® fasteners are specifically designed to eliminate tapping operations while forming strong threads in conventional magnesium die castings and similar materials, with minimal debris generation and good serviceability.

Minimizes debris generation in critical applications when driven into low-ductile materials; standard thread-forming fasteners with a 60° flank angle create excess debris. They can easily exceed the ductility limits of the material, causing damage to the formed threads.

Mag-Form® thread-forming fasteners feature a broader flank angle. When driven into low-ductile materials, such as magnesium die-castings, a compressive action forms strong threads in the material with minimal debris generation.

Mag-Form® fasteners also allow multiple removals and reinsertions, unlike standard thread-forming fasteners.

Automotive Sub Assembly

Because they produce minimal debris during installation, Mag-Form® fasteners are the optimal solution for critical applications such as steering components and airbag modules.

May exceed the ductility limit of the material, causing damage to formed threads

Compressive action forms strong threads in low-ductile materials

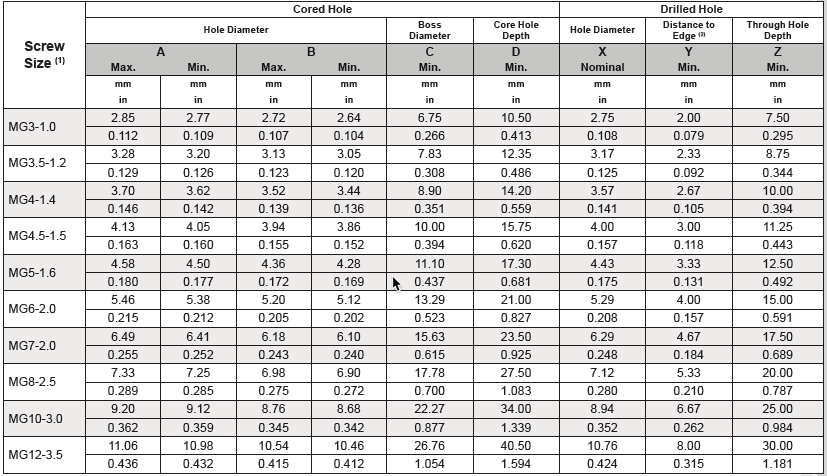

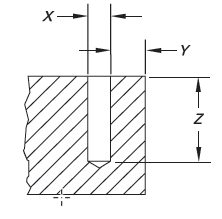

Mag-Form® Cored Hole Casting

Mag-Form® Drilled Hole Casting