Thread Rolling into Light Alloy without Compromise

High joint-strength

Safety against dynamic loads

Consistently high clamp loads

Self-locking vibration resistance

Easy lead-in, low drive torque

Opportunity to reduce installation depth

Wider hole and draft angles

Compatible with metric machine threads

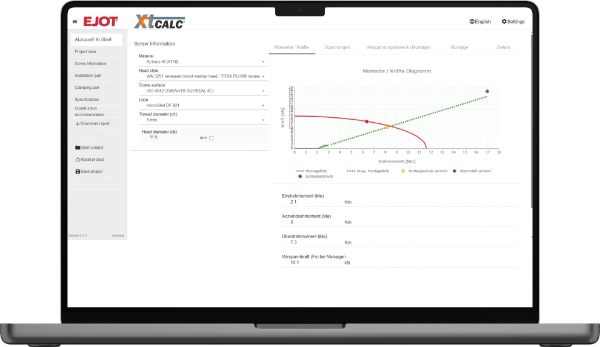

Xt CALC® Software validates applications, speeding up engineering development time.

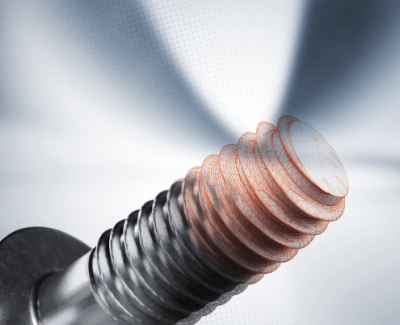

The small 33° flank angle of the ALtracs® Xt creates a stronger female thread in the mating material.

A circular body shape provides a larger area of thread engagement

Tapered thread forming lead-in with Progressive Forming Profile (PFP)

Thread compatibility - the ALtracs® Xt thread is designed to be completely interchangeable with metric machine thread

Components made from light alloy are ever-present in the industry, especially in the automotive sector. For this purpose, Semblex presents the ALtracs® Xt – a thread-forming screw optimized for use in light alloys.

Economic screw joints

Since the ALtracs® Xt is a thread-forming screw, specific processes on the way to a completely assembled screw joint can be omitted. This brings the potential for more cost-effective screw joints.

Smart design support

With the specifically developed prognosis software Xt CALC®, all relevant process parameters, as well as screw joint properties, can be reliably precalculated already during the developmental stages of projects.

Compact component design

The thread geometry is specialized for use in light alloys. This allows to generate high clamp loads with minimum space requirements for the screw joint.

Castable tolerances

Thanks to its forgiveness to hole tolerances - regarding diameter and draft angle - ALtracs® Xt is the ideal screw for cast pre-holes.

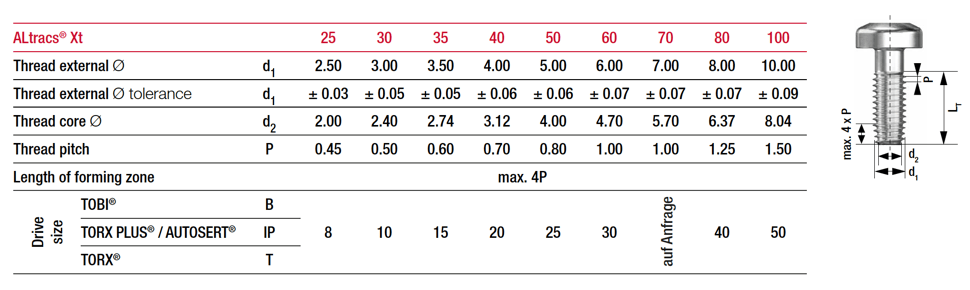

The ALtracs® Xt is a thread-forming screw in accordance with DIN 267-30 for use in light alloy (as well as other nonferrous metals) with a maximum tensile strength of 470 MPa as well as a hardness of up to 140 HB.

Every screw joint is only as strong as its weakest link. When using a hardened steel screw (with properties acc. property class 10.9) in light alloy, the light alloy usually is said to have weak links. The strength ratio between a steel screw (property class 10.9 with Rm ≥ 1040 MPa) and a typical light metal alloy (Rm approx. 330 MPa) is 3:1.

The specialized thread flank geometry of ALtracs® Xt compensates for this difference in strength, considerably lowering the risk of premature failure of the female thread. This allows high clamp loads to be realized at low installation depths.

At the same time, all the advantages of a thread-forming screw can be used.

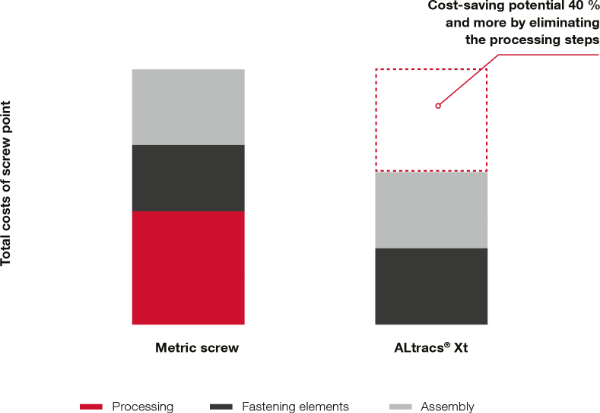

Economic screw joints thanks to ALtracs® Xt

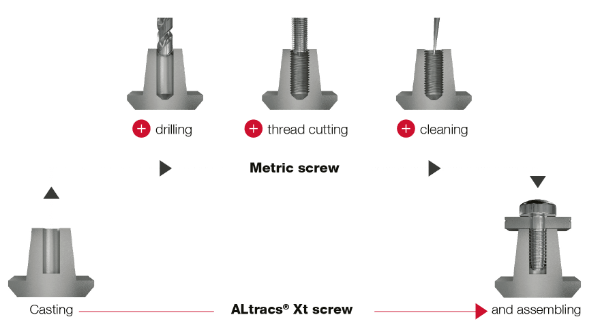

Thread-forming screws, in general, bring considerable economic saving potential compared to conventional machine screws.

When using machine screws in cast parts, additional machining processes like drilling and thread cutting (plus cleaning) are required. Each of these process steps costs time and money long before the assembly of the screw joint.

When using ALtracs® Xt, those additional process steps are not necessary.

ALtracs® Xt can be assembled directly into the conical pre-hole from the casting process without further machining.

Thus the total costs per screw joint are significantly reduced.

Comparison of Total Costs

Thread forming into light alloy without compromise

Thread forming into light alloy without compromiseSo far, there have been two established concepts for thread-forming screws.

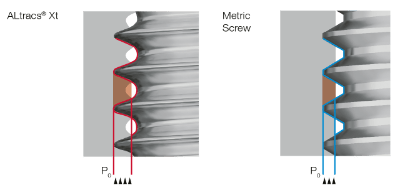

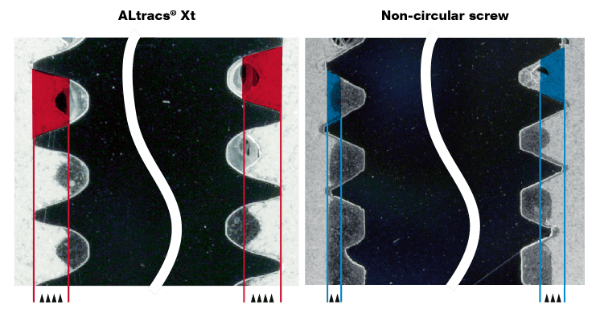

Circular cross-section

A circular cross-section increased the engagement between male and female thread. Thus, maximal joint strengths can be realized.

Non-circular cross-section

A non-circular cross-section has some void areas in the thread. The engagement doesn’t happen around the complete circumference. The advantage is low friction – especially during thread forming. Due to the smaller thread engagement, there is a risk of premature stripping of the female thread.

ALtracs® Xt – the best of two worlds

The optimization of the thread contour was inspired by nature. Compared to older thread designs, the contour is a lot rounder, leaving out areas that do not improve the joint strength but only cause friction. The new Progressive Forming Profile (PFP) also results from that development. With the friction-optimized thread contour at the tip (in the first four threads) of the screw thread forming torques can be drastically reduced, while the circular cross-section of the screw ensures that load-bearing capacity is high.

Thus, the innovative ALtracs® Xt combines the advantages of both concepts – without compromise!

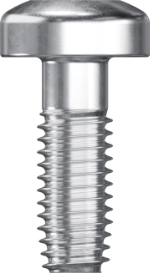

Compared to a conventional machine screw, ALtracs® Xt has a reduced flank angle of 33° instead of 60°. By reducing the flank angle of the screw, the thread tooth of the formed female thread will become more prominent. Combined with the female thread's cold-work hardening, this ensures a high load-bearing capacity of each thread pitch – even when faced with thermal stress. As such, the ALtracs® Xt offers further saving potential by reducing the space requirements for screw joints. This makes ALtracs® Xt the ideal fastener for lean designs in light alloy components.

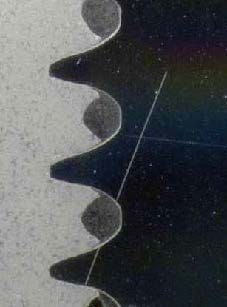

Metallographic cut of the play-free engagement between male and formed female thread.

Thread forming with ALtracs® Xt generates a play-free thread engagement between the screw and light alloy components. The large contact area between the male and female thread provides high thread friction. This ensures a high dynamic safety without further thread lockers like locking patches or underhead serrations.

When designing screw joints for various components, oftentimes, the same questions and challenges come up. ALtracs® Xt – combined with other Semblex technologies and services – solves many of those challenges. Oftentimes, further saving potential can be realized when incorporating your Semblex contact early during projects.

Compared to other thread-forming fasteners with a non-circular (polygonal) cross-section, ALtracs® Xt achieves maximum thread engagement thanks to its circular cross-section.

The available space will be used optimally.

With better flank engagement, ALtracs® Xt generates additional advantages:

Low space requirements

Already at relatively short installation depths of ~ 2.0xd1, ALtracs® Xt can generate clamp loads comparable to a property class 10.9 machine screw without damaging the female thread. Additionally, this high clamp load is also retained in the screw joint – even under the influence of thermic/dynamic stress – thanks to the more homogeneous load distribution.

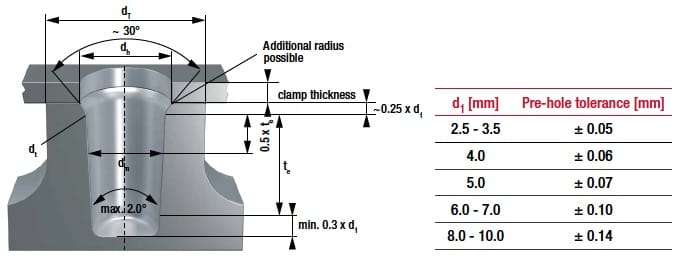

Bigger allowable tolerances

The maximum thread engagement of the circular cross-section helps to better compensate tolerances in the pre-hole, especially regarding pre-hole diameter and draft angle (in the case of a cast part). This is especially valuable when joining components produced in a die-cast process. ALtracs® Xt ensures a castable component design and thus allows for more economic cast parts.

Potential for miniaturization

Each thread pitch in a screw joint with ALtracs® Xt can bear a higher clamp load than what would be the case with other thread-forming fasteners. This allows a reduction of installation depth (or, ideally, even the reduction of the screw diameter) without impacting the integrity of the screw joint.

Semblex Engineering services offer the potential to save time/resources during the development stages of projects. Analytical design with Xt CALC® The reliable prognosis of design and process parameters like clamp load, torque values, or failure methods is essential for thread-forming assemblies. Therefore, Semblex provides the specifically developed prognosis program Xt CALC®. This software allows the designing of screw joints with ALtracs® Xt.

Services for maximum efficiency

State-of-the-art simulation tools and high-quality material models allow for a realistic simulation of the fastener’s influence on the complete component. Together with the testing capabilities at Semblex, this will enable us to cover a wide range of aspects of joining technology.

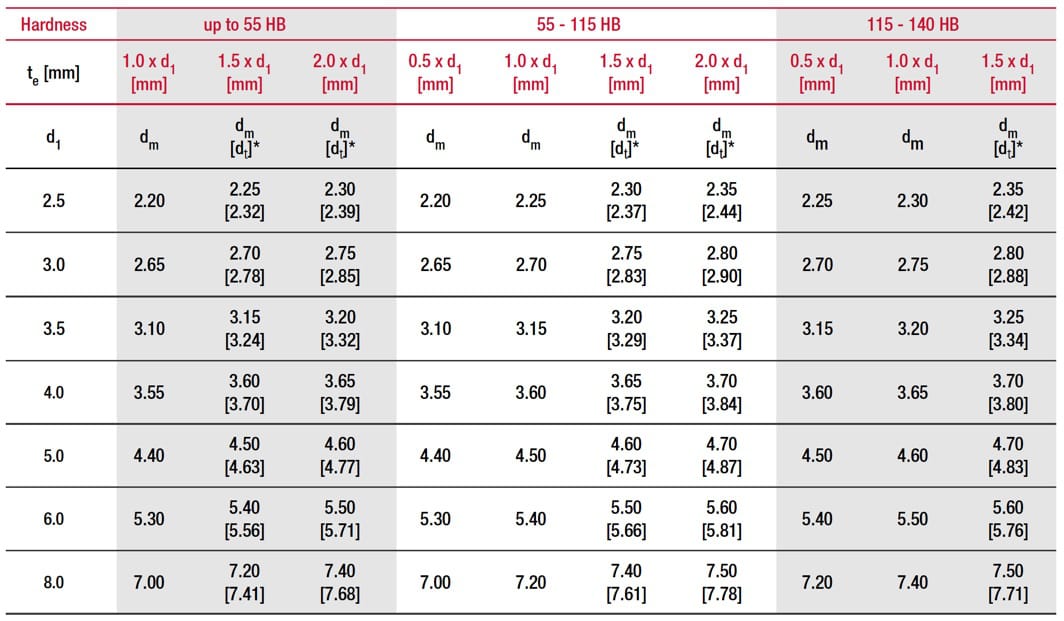

The hole diameter recommendations in the table apply to light metal and other non-ferrous metals with a strength of ≤ 470 MPa and a hardness of ≤ 140 HB. For higher material hardness, we recommend other thread geometries. The values are based on laboratory tests, so the assembly parameters, especially the influence of the screw surface, should be checked before starting production. The Semblex Engineering provides the required application technology for this.

Hole recommendations for cast and drilled holes with alloys of aluminum, magnesium, zinc, and copper with different screw-in depths (te)

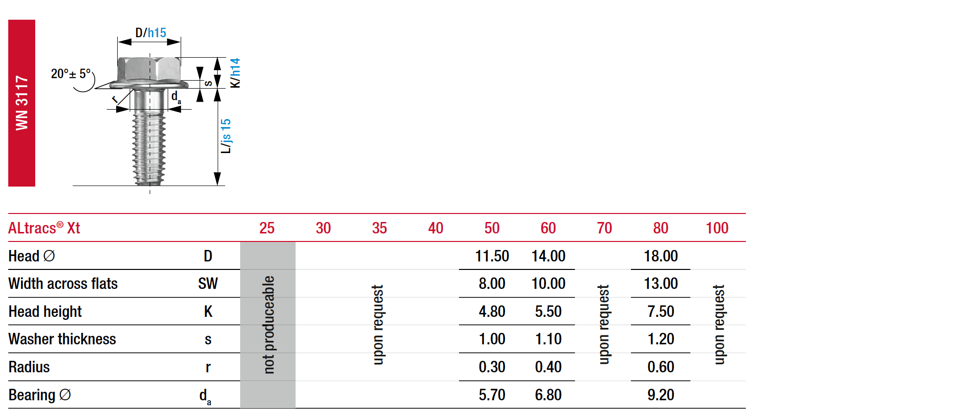

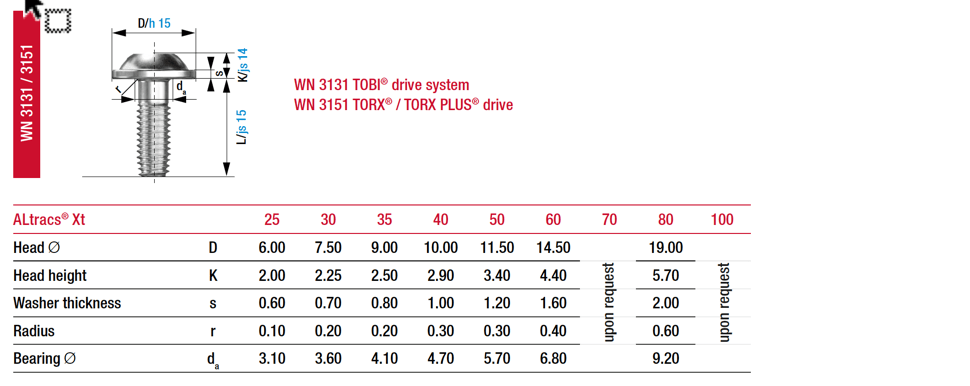

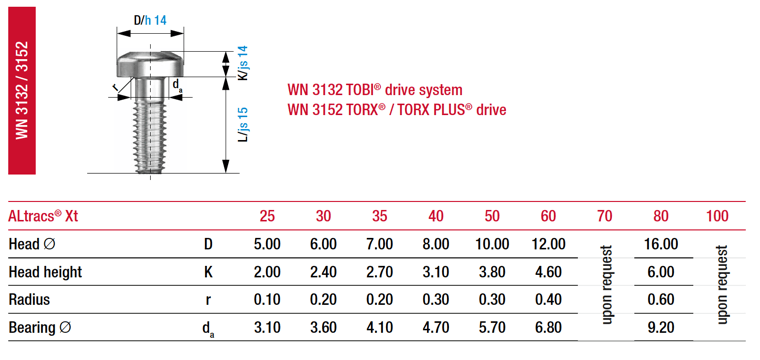

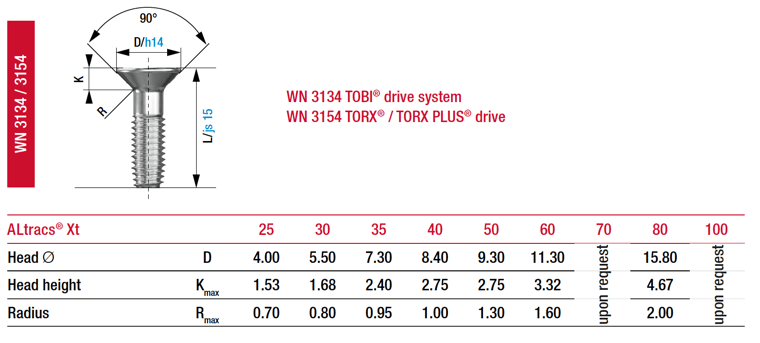

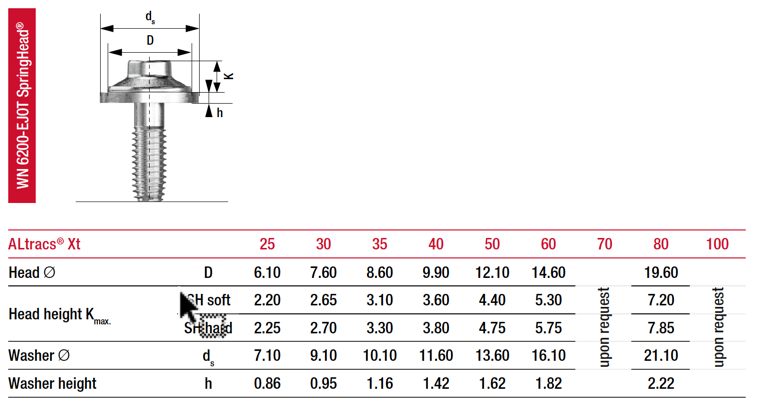

All dimensional data in mm