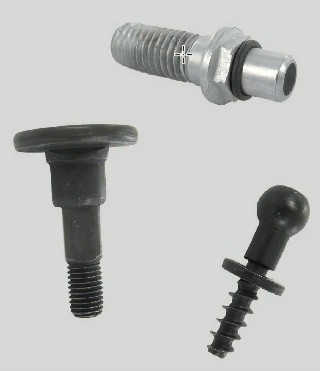

Semblex specializes in complex shapes and designs. No two applications may be alike and may require a functioning “special” to fulfill the demanding requirements.

Multi-die heading capabilities range from 2 dies 3 blow headers for miniature screws up to 6 die 6 blow for large diameter products.

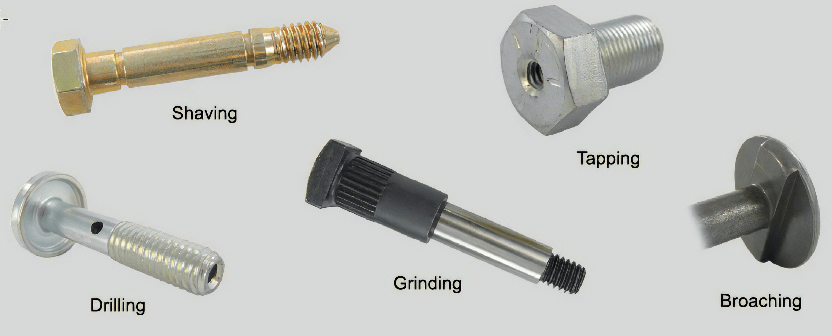

In-House drilling supports a wide variety of parts and industries: From brake assemblies, vented fasteners, to specialized applications with critical requirements.

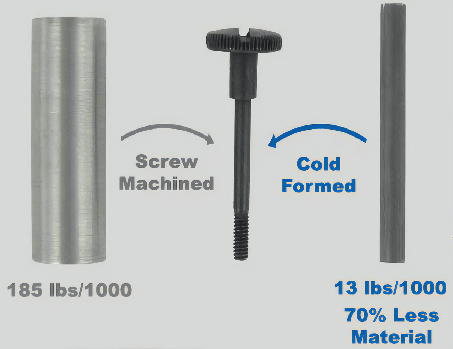

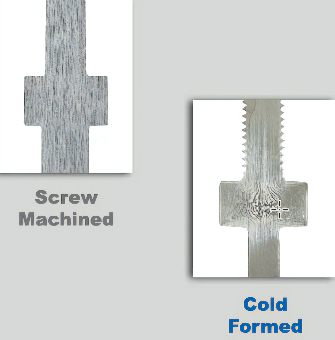

Significant cost savings through scrap reduction (as material is moved not removed)

Improved product strength with cold forming process

Tight tolerances can be achieved

Combines multi-piece components into one piece designs

Eliminates part numbers to be managed

Simplifies assembly process and reduces cycle time

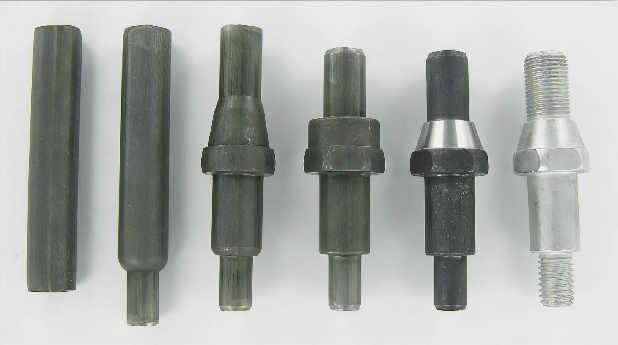

Cold Forming is the process of forming metal at ambient temperature to produce 'Net' or 'Near Net' Shapes resulting in material cost savings, increased production rates and consistent quality parts. Cold Forming produces shapes by the movement or shaping of material versus the removal of material so virtually no material is wasted. Because the shape is produced by manipulating volume the grain flow follows the part configuration which provides a higher resistance to fatigue and fractures resulting in a stronger part. The ever expanding Cold Forming Technology allows for increasingly complex configurations produced at very high rates thus reducing costs and improving design flexibility.

The Cold Forming Process can provide a wide range of 'Net' Shapes, allowing for optimum savings to the product and the assembly. When additional features or precision tolerances are required, the Cold Forming Process can complement the secondary processes to meet application requirements. This combination of processes provides high-quality, value-added products and enhanced performance.

Large features relative to the shank or body of the part

Multiple sections or diameters

High production quantities

Material cost is a significant portion of the part's total cost

Applications with high dynamic loads

Designs that require complex shapes or extrusions

Tight tolerances and positional requirements

High surface finish requirements

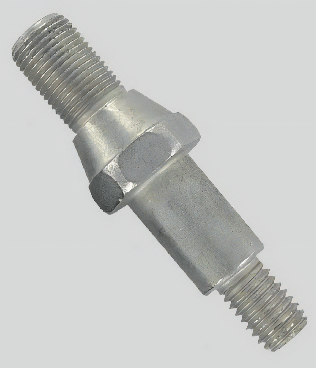

Application: Motorcycle Suspension Bolt

Opportunity:

Process:

Benefits:

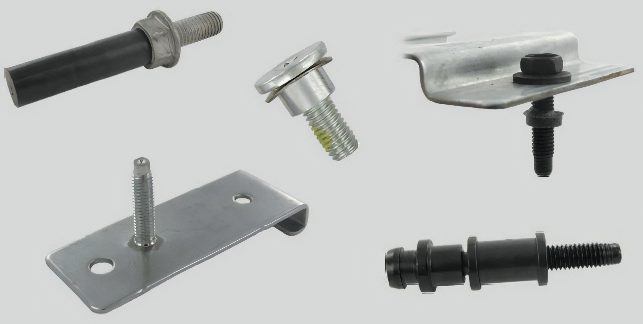

Discover cost reduction opportunities by working with Semblex and our partners to combine Cold Formed Specialty Components, fasteners, plastics, stampings, and other items into simple , complete assemblies.

Benefits Include:

Benefits Include:

Part consolidation

Vendor reduction

Outsourcing of simple components

Inventory reduction

Labor savings

Carbon Steel:

Medium Carbon Steel:

Alloy Steel:

Stainless Steel:

Aluminum:

Other:

Copper, Brass, Bronze

At Semblex, Cold Formed Specialty Components are an important means to meet our customer's needs and exceed their expectations. We accomplish this not only with our equipment but with our team-driven approach. This approach starts with our team working with our customer to understand their needs and the application requirements. Our team's experience and process knowledge allow us to evaluate requirements and ensure the most stable, cost-effective processes are used. During this activity, we identify opportunities for cost savings and improve the product's performance. This lets us connect our customers' needs with the best, most cost-effective processes.

What is Cold Heading you ask? Discover...

The Cold Hard Facts of Cold Heading (722 KB)