The Evolution of Direct Fastening into Plastic

EVO CALC® Software validates applications, speeding up engineering development time

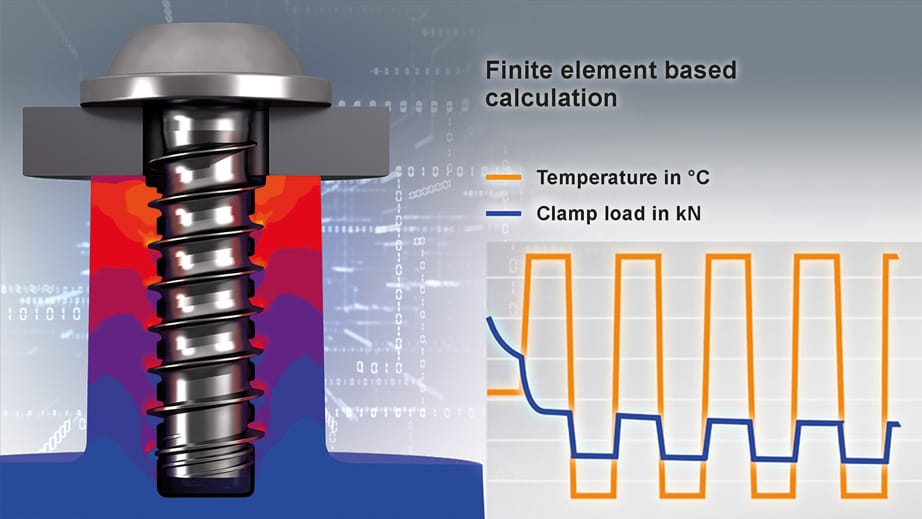

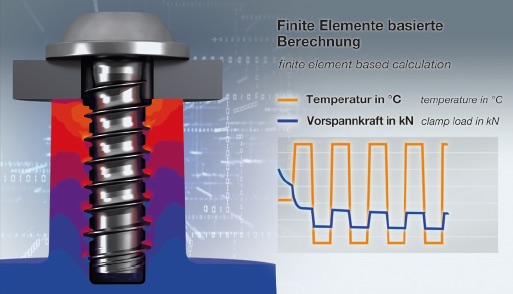

FEM based relaxation forecast under temperature and time

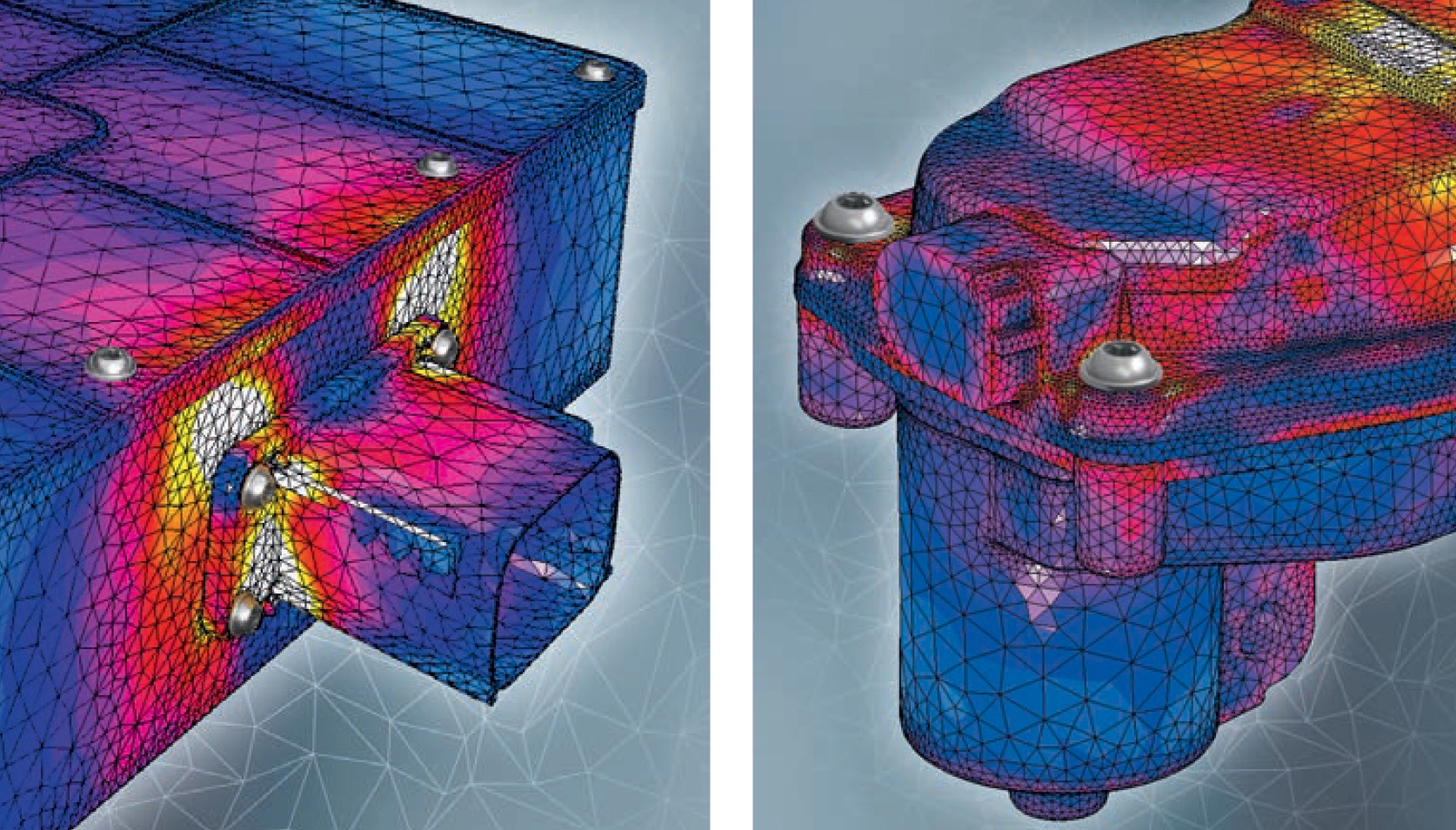

CAE- Computer-Aided Engineering for complete assembly groups

Standardization potential of single screw length due to unique thread forming zone approach

EVO-Effect (Low installation torque and larger drive to strip window)

The EVO PT® is the evolutionary development of the self-tapping screw for thermoplastics. With this innovative fastening solution, EJOT has successfully combined production and application technology knowledge with new methods based on physical computer simulations for the first time.

The digital calculation service EVO CALC® offers the possibility to pre-calculate the torques and clamp loads and the clamp load relaxation under temperature and time. Furthermore, EJOT provides an individual, FEM-based component analysis to save valuable time and money - beginning with the component's design.

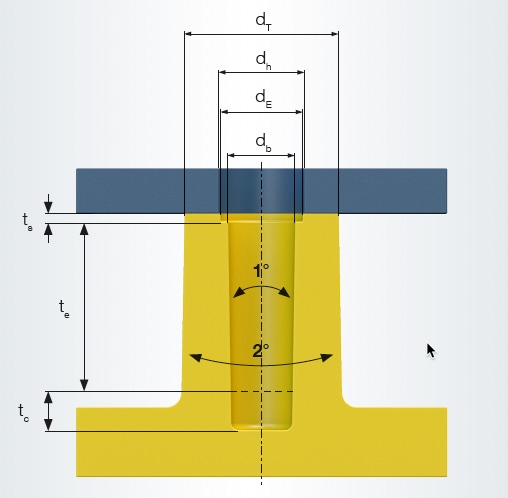

Since the forming thread turn generates a virtually constant forming torque, a compensation of different clamping part thicknesses using different counterbore depths is unnecessary. As we assume to have injection-molded pre-holes, which usually have a draft angle of 1°, the pre-hole diameter of 0.85 x d1 is measured at the top of the pre-hole. For better measurability, the pre-hole diameter db at the top of the pre-hole is given as 0.85 × d1.

The newly developed "start-of-thread" of the EVO PT® allows for easy and straight positioning in the screw hole. The unique positioning thread thus generates an equal load distribution over the circumference of the thread flanks in the installed condition since the screw is centered automatically in the screw hole during the installation.

The innovative forming thread turn creates a torque curve virtually independent of the installation depth during the installation phase. The thread-forming zone forms a thread turn into the female material, slightly larger than the clearance the following thread turns require. The following thread turns can penetrate into the plastic without any appreciable friction. This enables smaller installation spaces or a standardization of screw lengths and tightening torques.

Nominal diameter of the screw: d1

Counterbore diameter:

dE = d1 x 1.05

Hole diameter:

db = 0.85 x d1 ± 0.05 mm

Installation depth:

te = 2 x d1 or deeper

dT = external boss Ø

dh = clearance hole Ø

dE = counterbore Ø

db = hole Ø

ts = counterbore depth = 0.1 x d1

te = installation depth

tc = hole depth allowance

Thread forming zone

Thread forming zoneReduced friction during thread forming

Thread-forming torque is virtually independent of the installation depth

Installation-depth-independent

tightening torques

Reduced parts variety - one screw, one tightening torque per assembly group

Uniform tube design

Supports carry-over part strategies

High installation reliability

High plant availability

Compensation for process fluctuations

Lead-in thread

Lead-in threadAutomatic centering of the screw in the screw hole

Stable installation process during initial assembly

Line-integrated, fully automated repeat assembly

Constant, low-stress surface connection

Less installation space is required

Usage of purchased parts possible without unloading

Compensation of component tolerances

Bionic Contour

Bionic ContourSafety margins for challenging applications

Higher fatigue strength

Higher breaking torque

Higher tensile-breaking stress

26° flank angle

26° flank angleExcellent plastic forming

One flank geometry, suitable for all common thermoplastics

Reduced radial load in the component

Our role is to support your design work even before your customer orders. Together, we can incorporate the positive benefits of direct fastening into plastic into your assembly application at an early stage. At the end of the day, the new EJOT EVO PT® is all about you, a better result for your customer, and, ultimately, your economic success.

We want you to

• plan and produce in a cost- and time-optimised way

• produce process reliably and without errors

• enthuse your customers with your quality before and after the order placement

• receive the order

• quickly have your product ready for serial production

As a manufacturer of products and components, you not only have to control your production, but every process in your company impacts your overall success. That‘s why we keep an eye on the requirements of all persons involved in the overall process and provide you with measurable advantages thanks to the EVO PT®.

When configuring and using EVO PT® screws, you may benefit from these exclusive services:

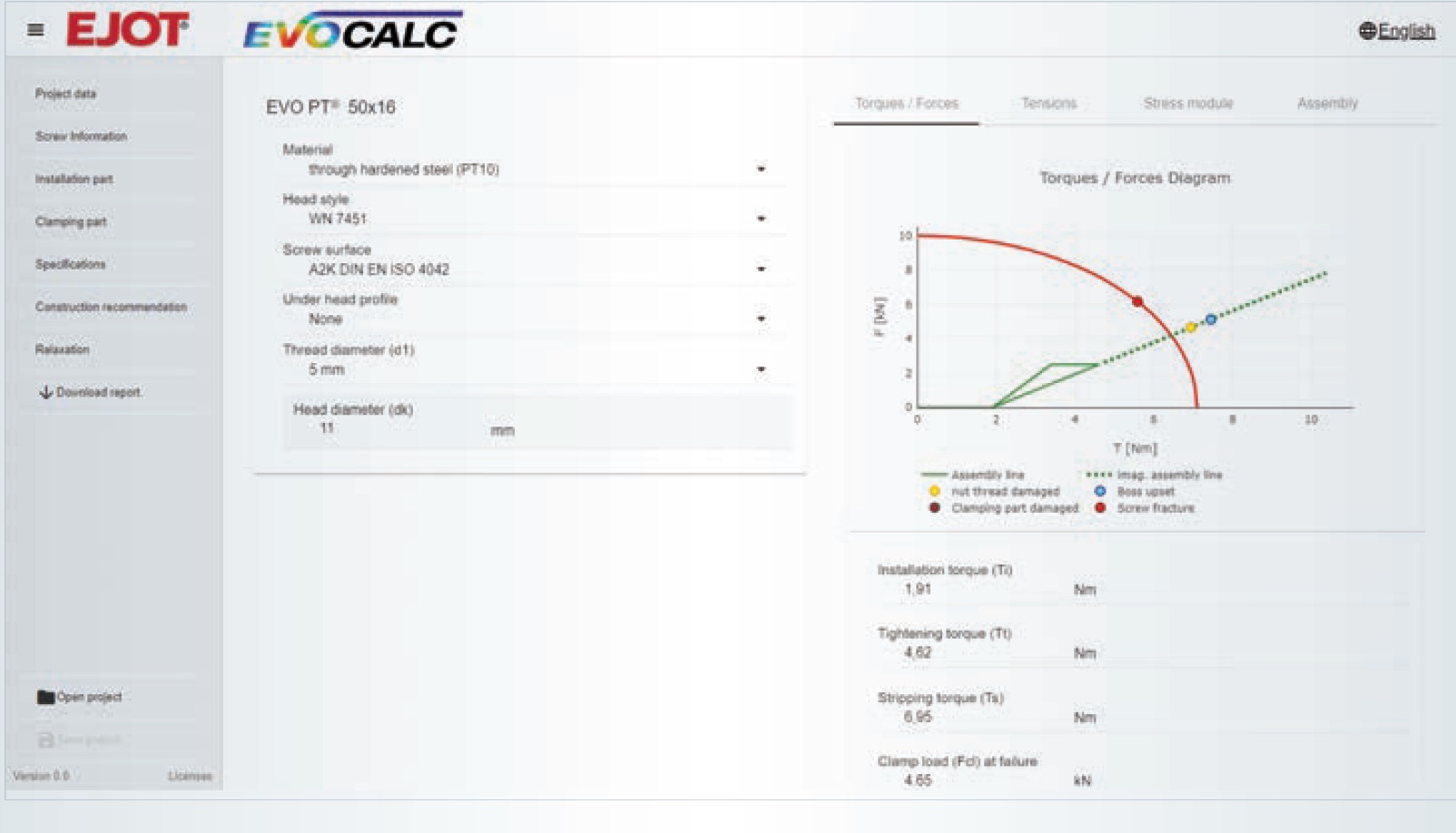

The prognosis program EVO CALC® especially developed for this screw enables the fast and precise determination of all values and information concerning the installation of the EVO PT®, which are essential for your project.

This comprises, for example, creating a design recommendation, calculating the relevant torques, determining different forces, such as the clamp load at the tightening torque, and presenting possible failure modes in case of overload. The results provide immediate information on whether your assembly group is already optimally designed for your requirements or what has to be done to achieve your optimum.

If you have any further questions, please do not hesitate to contact your application engineer.

Details are taken from the prognosis program EVO CALC®.

Advantages