Next-Generation Flow Drill Fastener

Fastening into up to 10mm thick aluminum without clearance holes

Eliminating clearance hole collisions with high-strength top layers

Resisting joint leaks with or without clearance holes

Reducing installation time

Suppressing debris through improved point geometry

Improving material flow in brittle casting materials

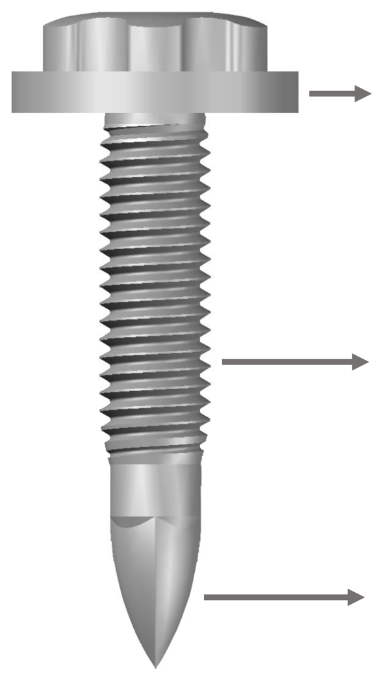

The OptiFlow® fastener's modularity allows the designer to build their custom solution by selecting different head, thread, and tip design features to optimize required installation and joint performance.

|

HEAD |

|

|

DU: |

|

|

LW: |

|

|

SL: |

|

|

SH: |

|

|

FS: |

|

|

TD: |

Traditional |

|

THREAD |

|

|

FF: |

|

|

RH: |

|

|

TD: |

Traditional (Metric) |

|

TIP |

|

|

LT: |

|

|

HP: |

|

|

LH: |

|

|

TD: |

Traditional |

OptiFlow® is the latest flow-drilling fastening technology capable of hole forming and self-threading into target mating materials. Flow drill fasteners utilize a pointed tip and frictional heat to soften substrate materials, allowing a hole to be “flowed” through them before forming threads into the created hole. OptiFlow® was developed to improve traditional flow drill fastener designs, such as FDS®. Traditional flow drill fastener designs are over 25 years old and have several limitations, reducing their utilization in modern manufacturing. Some limitations include the inability to penetrate thick or high-strength materials, lack of leak resistance, downtime due to clearance hole collisions, poor bushing formation in castings, and debris generation. OptiFlow® takes an innovative modular approach to flow drill fasteners. OptiFlow® comprises various design innovations to traditional flow drill fasteners. Each design innovation solves a limitation of traditional flow drill fastening, and the designs can be combined to optimize the fastener for each application or range of applications.

OptiFlow® is the latest flow-drilling fastening technology capable of hole forming and self-threading into target mating materials. Flow drill fasteners utilize a pointed tip and frictional heat to soften substrate materials, allowing a hole to be “flowed” through them before forming threads into the created hole. OptiFlow® was developed to improve traditional flow drill fastener designs, such as FDS®. Traditional flow drill fastener designs are over 25 years old and have several limitations, reducing their utilization in modern manufacturing. Some limitations include the inability to penetrate thick or high-strength materials, lack of leak resistance, downtime due to clearance hole collisions, poor bushing formation in castings, and debris generation. OptiFlow® takes an innovative modular approach to flow drill fasteners. OptiFlow® comprises various design innovations to traditional flow drill fasteners. Each design innovation solves a limitation of traditional flow drill fastening, and the designs can be combined to optimize the fastener for each application or range of applications.