Stable Drive System

Benefits

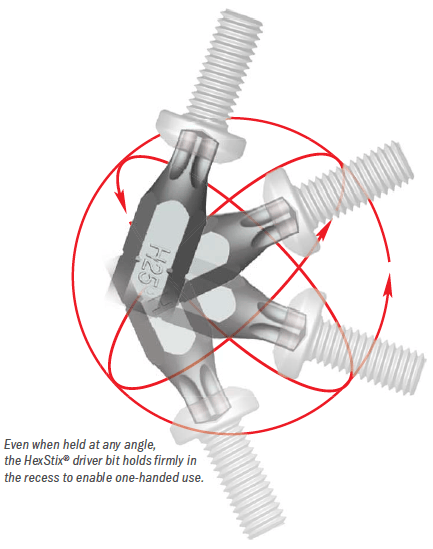

Easy one-handed operator assembly

Eliminates magnetic bit holders

Eliminates dropped screws in assembly area

Interchangable with 6-lobe driver bits

Features

Ensures screws stick in bit

Superior stability and axial alignment

Replaces traditional 6-lobe designs

Meets industry strength standards for lobular drive system

HEXSTIX® STABLE DRIVE SYSTEM

Applications

Driver Sizes:

H15 THRU H50

Screw Sizes:

M3.5 (#6) THRU M10 ( 7 /16 IN)

Transmissions

Trans-Axles

Differentials

Instrument Panels

Suspension Components

Suspension Components

Interior Components

Door Panels & Attachments

Door Frames & Hinges

Seats & Restraint Systems

Accessories & Attachments

Body Components & Attachments

Engine & Drive Train Components

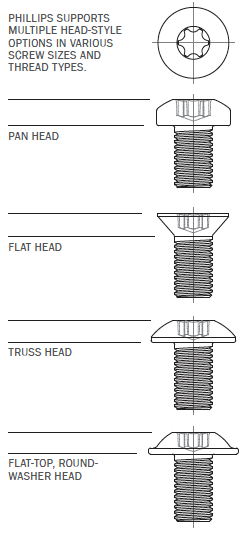

Machine Screws

Thread-Cutting Screws

Thread-Forming Screws

Overview

Engineered to deliver exceptional stability and alignment in one-handed applications.

The HexStix® Stable Drive System increases speed and efficiency in one-handed applications of assembled components. The screw recess design has an outstanding ability to hold firmly to the driver bit at the point of assembly - with no magnetic bits or vacuum screw holders required. From maintenance and field use, standard driver bits can be used to remove or replace HexStix screws.

Minimum Ultimate Torque

Bit strength is an important parameter in the design of internally driven fasteners. It's the starting point for determining the appropriate fastener diameter, head style, and size and indicates the type of material to be used.

HexStix® Drive System strength performs similarly to six-lobe drive systems currently available. The table below lists the minimum torsional requirement that bits must withstand under standardized testing for each size designated.

|

HEXSTIX® |

Approximate |

Minimum |

Minimum |

|---|---|---|---|

|

H15 |

#6(M3.5) | 70 | 7.9 |

| H20 | #8(M4) | 115 | 13.0 |

| H25 |

#10 (MS) |

170 |

19.2 |

|

H27 |

#12 (MS) |

240 | 27.1 |

| H30 |

1/ 4 (M6) |

335 |

37.8 |

| H40 |

5/16 (M8) |

575 | 65.0 |

| H45 |

3/8 (M8) |

910 | 103 |

| H50 |

7 /16 (M10) |

1,400 | 158 |

Phillips recommends NOT exceeding SO% of Minimum Ultimate Driver Bit Torque for optimum bit life. Contact Phillips for the appropriate drive size selection.

Values shown in the tables are to be used as a guide only. They are subject to change without notice. Please refer to the appropriate Phillips drive systems standards for current information.

HexStix® Drive System: The 360° fastening solution.

Screws are securely engaged on bits before application. No matter what orientation or whether the drive tool is operating-the, screws will not drop off. Additionally, unwanted contact with adjacent components during assembly or while operating in blind spots will not affect the effectiveness of the stick-fit. Once the screw is tightened in the application, the bit is easily removed.