Push-In Insertion Fasteners for Thermoplastics

Ease of assembly

Pull-out force higher than insertion force

Part removal is possible due to helix design

Tamper resistance when supplied without a drive

TRILOBULAR® body

Asymmetrical thread form

Helical thread design

Can be produced with or without a drive system for security

PUSHTITE® II TRILOBULAR™ fasteners are designed to be pressed into recommended hole sizes with a single, straight-line stroke. They can be used in various thermoplastics of widely varying densities.

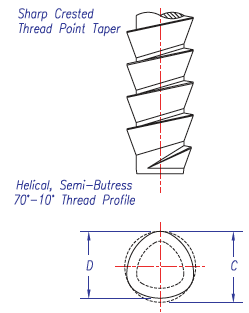

PUSHTITE® II fasteners combine a 3-lobe thread form with a 70º – 10º semi-buttress thread shape to permit easy entry and provide exceptional pull-out resistance.

Threads are helical, not annular, permitting displaced air to escape during insertion.

The helical thread form also allows the fasteners to be removed and reinserted if necessary.

Recommended length of thread engagement is two screw diameters minimum.

The range of suggested hole sizes is large because of the range of densities in thermoplastic compounds and the length of thread engagements. Generally, low-density plastic can use smaller hole diameters. Long lengths of engagement (2.5 to 3 diameters) require larger holes.

Tamper Resistant yet Removable for Service. PUSHTITE® II fasteners are normally available with a drive system in the head for removal, adjustment, or final tightening. Where adjustment or removal is not required, they are available without a slot, recess, or socket in the head.

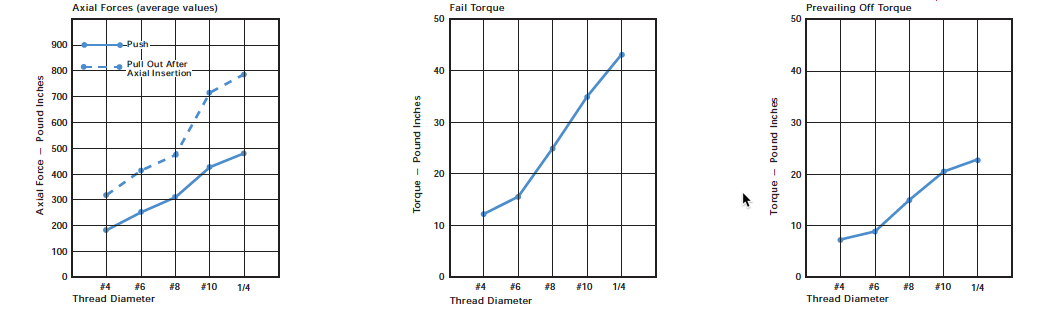

Graph performance is based on the average of several tests in different materials.

MATERIAL:

Low Carbon Steel, Suitably Hardened and Tempered

FINISH:

As Requested

LENGTH TOLERANCES:

Nom. Length

Thru 3/4"

Over 3/4”

Over 1/4” Dia.

All Lengths

Tol.

±.030”

±.050”

±.050”