The Fastener Solution for Thermoplastics

Reduces radial stresses

Allows for thinner boss design

High resistance to pullout forces

Provides repeat assembly

Minimizes clamp load loss

30° thread angle

Optimum pitch

Profile thread root

Round cross section

Given the fact that relaxation and stress cracking tendencies increase with clamp load, it is recommended that the specific tightening torque should be the minimum required rather than the maximum achievable.

In addition to being aware of the effect of excessive torque on the assembly, attention must also be paid to the driver's speed. As the fastener is rotated, heat is generated within the assembly. This heat is instrumental in allowing the plastic to flow into the thread’s root diameter, provided it is controlled.

When the speed becomes too high, excessive heat is created. This heat can then have a negative impact on the overall assembly profile...

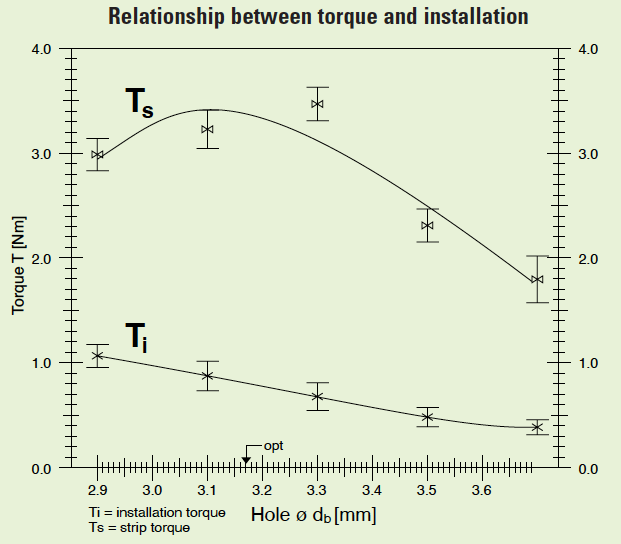

The graph to the right exemplifies the relationship between torque and the hole diameter. The optimum hole diameter is selected based on the widest margin between the installation and strip torque.

Material: ABS

Fastener:

K40 x 16 PT®

Torx Pan Head

Installation Depth: 8mm