Multi Featured Drive System

Benefits

Multi-drive system for field serviceability

High torque transfer

Reduced cam-out

Features

Engineered recess design that improves the feature of the square drive, allowing servicing with a Phillips and square driver

Unique Quadrex™ bits

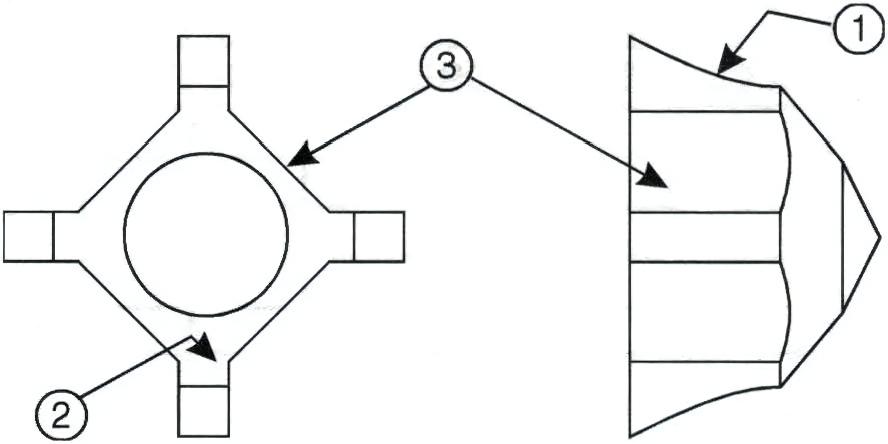

WHAT IS QUADREX?

Quadrex® is not a Phillips/square combination but an engineered recess design that improves the features of the square drive, allows servicing with a Phillips or square driver, and offers superior driving performance with Quadrex drivers.

Quadrex is an established drive system in the U.S., Canada, and Europe utilized in industries such as appliance, automotive, electrical, furniture, construction, and many others. Because of its simple configuration and wide range of capabilities, Quadrex is being introduced into new applications every day.

The design characteristics that make Quadrex so unique are:

- The radial end walls of the recess wings, which provide an optimal penetration depth for a Phillips driver without compromising head strength or service performance;

- The open corners of the square portion of the recess improve driver penetration and eliminate any sharp corners that encourage stress cracks during the fastener head forming stage and;

- The vertical recess side walls improve total engagement and increase overall recess strength.

WHY IS QUADREX THE RECESS OF CHOICE?

Four major factors contribute to defining what a quality recess should offer:

- Flexibility of design

- Compatibility with high-production assembly

- Consistent products and reliability

- Availability of drive system

FLEXIBILITY OF DESIGN - The Quadrex® recess is generally manufactured in 5 sizes. Table (1) lists the comparable square drive size and proper Phillips service driver accepted by each Quadrex size:

|

QUADREX |

SQUARE |

PHILLIPS |

|---|---|---|

|

#0 |

0 |

1 |

|

#1 |

1 |

2 |

|

#2 |

2 |

2 |

|

#3 |

3 |

3 |

|

#4 |

4 |

4 |

Table (1)

Within each Quadrex size, a range of standard recess depths is available to the product designer. This allows the designer to easily apply Quadrex to various fastener head styles regardless of head configuration, thus helping streamline product development. Standard recess depths are produced in terms of their comparable square depths for simplification. They are coded and displayed in Table (2) along with the square depth ranges they respectively fall into:

QUADREX RECESS SIZE

|

SQUARE |

#0 |

#1 |

#2 |

#3 |

#4 |

|---|---|---|---|---|---|

|

.024 - .030 |

Q-01 |

|

|

|

|

|

.030 - .040 |

Q-02 |

Q-11 |

Q-21 |

|

|

|

.040 - .050 |

Q-03 |

Q-12 |

Q-22 |

|

|

|

.050 - .060 |

|

Q-13 |

Q-23 |

|

|

|

.060 - .070 |

|

Q-14 |

Q-24 |

|

|

|

.070 - .080 |

|

Q-15 |

Q-25 , Q-26 |

Q-31 |

|

|

.080 - .090 |

|

|

Q-27 |

Q-32 |

|

|

.090 - .100 |

|

|

Q-28 |

Q-33 |

Q-41 |

|

.100 - .110 |

|

|

|

Q-34 |

Q-42 |

|

.110 - .120 |

|

|

|

Q-35 |

Q-43 |

|

.120 - .140 |

|

|

|

Q-36 |

Q-44 |

Table (2)

Table (2) shows that the depth ranges overlap and are expected to have more than one recess size. This gives the option to choose a larger recess size for the same head style without severely affecting the fastener head strength. This is further demonstrated in Table (3), which matches recommended Quadrex® recess sizes with various screw sizes and head configurations:

|

Quadrex |

Flat |

Flat Head |

Oval |

Pan |

Truss |

Fillister |

Round |

Round |

|---|---|---|---|---|---|---|---|---|

|

#0 |

4 |

4 |

4 |

4 |

4 |

4.5 |

4 |

4 |

|

#1 |

5, 6, 7 |

5, 6, 7 |

5, 6 |

5, 6, 7 |

5, 6, 7 |

6, 7, 8 |

5, 6 |

5, 6 |

|

#2 |

7, 8, 9, 10 |

6, 7, 8, 9, 10 |

6, 7, 8, 9, 10 |

6, 7, 8, 10 |

6, 7, 8, 10 |

10 |

7, 8, 10 |

6, 7, 8, 10 |

|

#3 |

12, 1/4 |

12, 14, 16 |

12, 1/4 |

12, 1/4 |

12, 1/4 |

12, 1/4, 5/16 |

12, 1/4, 5/16 |

12, 1/4, 5/16 |

|

#4 |

5/16 3/8 |

18.20 |

5/16 3/8 |

5/16 3/8 |

5/16 3/8 |

3/8 |

|

|

Table (3)

COMPATIBILITY WITH HIGH PRODUCTION ASSEMBLY- A drive system must exhibit considerable reliability due to the brief time windows allowed for multiple installations in large-volume manufacturing. Delays caused by chronic recess failures can have a significant ripple effect on the efficiency of the whole production line. In most instances, fasteners must be installed as the assembly constantly moves past the worker. This places more pressure on the operator to be as efficient as possible from a relatively fixed position on the line. Compounding this problem is that not all fastener installation points are accessible enough to allow optimal (axial) driving. Given these circumstances, the two main characteristics that a manufacturer should look for in a production line drive system are:

- Ability to transmit sufficient torque to the fastener (axially or off-angle driving) until the required clamp load is achieved,

- A recess that minimizes time and resources dedicated to assembly and, simultaneously, can substantially decrease immediate assembly costs and long-term overall manufacturing costs.

Additional Family Products

PLUS

PLUS

Same features and benefits of Quadrex™ with added serviceability from addition of slot.