Drive System

Benefits

Provides high torque transfer

Increased tool engagement

Inch and metric in one tool

Consistent bit engagement in small fasteners

Features

Straight vertical sidewalls

Lobed engagement

Broad contact surface

The Need for an Improved Drive System

The drive system you select for your assembly line affects joint reliability, worker safety, downtime, and product quality.

There are many drive systems available today. However, because of weaknesses inherent in their design, they may cause problems on the assembly line and in the field.

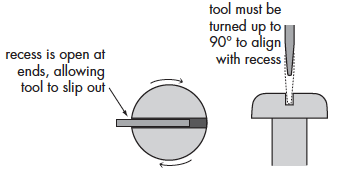

Slotted Systems

Slotted Systems

- Tool slippage is common, which can cause damage to surrounding surfaces

- Drive tools tend to chip or round off at corners

- Not compatible with automated assembly

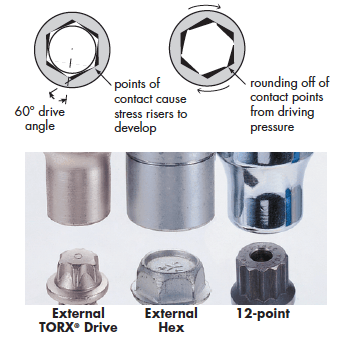

Hex Systems

Hex Systems

- Point-to-surface contact between the hex drive tool and the fastener head often leads to rapid tool wear and can distort the fastener head as torque increases

- A 60° drive angle is inefficient for torque transfer

- Stress is concentrated at the corners of the hex socket, which can cause the socket to fail at these stress points

- The diameter of the hex drive socket is normally greater than the bearing surface of the fastener, forcing engineers to design for socket clearance

12-Point Drive

- Since the 12-point drive is simply a double hex drive, the problems of point-to-surface contact, inefficient 60° drive angle, and stress risers still exist

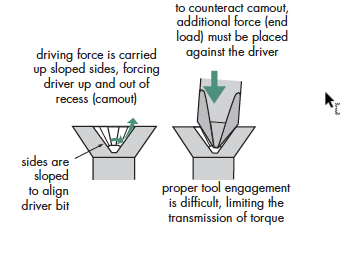

Cruciform Systems

Cruciform Systems

- Inclined side walls of the cruciform drive deflect torque upwards, which causes the driver to “camout”

- Camout and its limits on torque transfer can prevent a fastener from being fully seated

- Excessive end loads, required to prevent camout, can reduce bit life and cause worker fatigue and injury

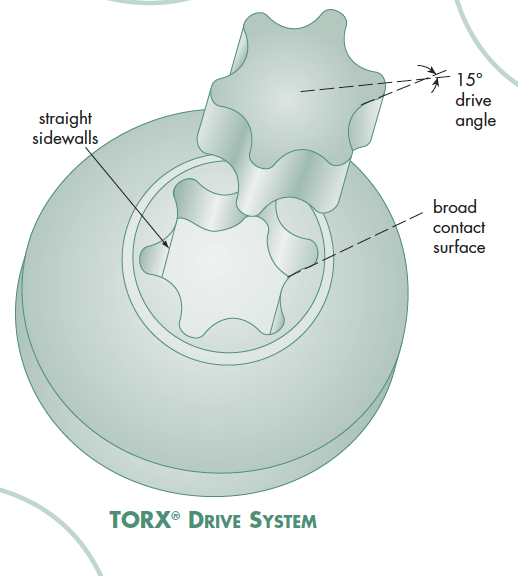

Features and Benefits of the Torx® Drive System

The TORX® Drive System was specifically designed to provide a simple, cost-effective solution to the problems inherent in the process of installing and removing fasteners. Used in many industries, the TORX Drive System can enhance product reliability, increase productivity, and reduce total assembly costs, which are keys to remaining competitive in today’s marketplace.

15° Drive Angle

- Provides high torque transfer

- Radial forces are drastically reduced, resulting in a longer tool life

Straight, Vertical Sidewalls

- Increases tool engagement

- Unlike cruciform drive systems, no camout forces are created to push the driver up and out of the fastener

- Since camout is virtually eliminated, little or no end load is required

- Ergonomic studies have shown the TORX Drive System can reduce fatigue and muscular stress during the manual assembly of fasteners

- Recess completely encloses drive bit, minimizing tool slippage and the damage and injuries it can cause

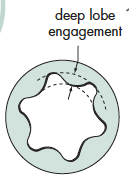

Broad Contact Surface

Provides greater depth of lobe engagement between the driver and the fastener

Provides greater depth of lobe engagement between the driver and the fastener- Allows driving forces to spread over a broader surface, as opposed to the point contact of many drive systems

- Allows more efficient torque transfer

- Extends tool life

Inch and Metric in One Drive Tool

- Same-sized drive tool seats both inch- and metric-sized fasteners

- Add or convert to metrics later without a tooling change