Spiral Drive System

Extremely high torque transfer

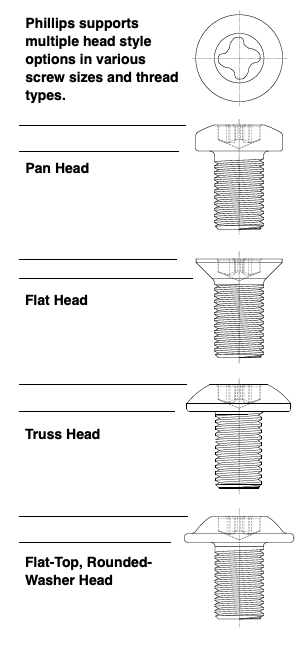

Allows for lower head profiles

Less fastener weight

High bit strength

Driver Sizes:

MTS-000 Thru MTS-8

Screw Sizes:

M2 (#2) Thru M20 (7/8 IN)

Transmissions

Trans-Axles

Differentials

Instrument Panels

Machine Screws

Suspension Components

Interior Components

Door Panels & Attachments

Door Frames & Hinges

Seats & Restraint Systems

Accessories & Attachments

Body Components & Attachments

Engine & Drive Train Components

Thread-Cutting Screws

Thread-Forming Screws

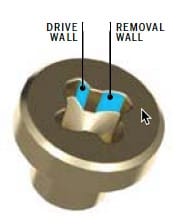

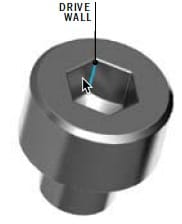

The Mortorq® Super high-strength spiral drive system is today's most advanced industrial drive system in automotive/transportation manufacturing. Featuring an exceptionally shallow recess, it sets the standard for strength and functionality. Its recess geometry provides complete driver contact over the entire mating surface of the recess wings. This results in extreme high-torquing capability without risk of damage to the fastener or surrounding head area. Minimal head height reduces the weight of fastened components. Made with less material and light in weight, Mortorq Super contributes to greener automotive products.

Bit strength is an essential parameter in the design of internally driven fasteners. It's the starting point for determining the appropriate fastener diameter, head style, and size and indicates the type of material to be used.

Increased recess removal wall contact area provides higher removal torque capabilities for service environment conditions where corrosion or galling affects the removal of screws.

Coatings in the drive recess can cause improper or misaligned bit engagement. With added clearance between the bit and recess, Mortorq Super Spiral Drive System provides added robustness in the handling and assembly of screws.

|

MORTORQ® |

Approximate |

Minimum |

Minimum |

|---|---|---|---|

|

MTS-000 |

#2, #3 (2) |

12 |

1.36 |

|

MTS-00 |

#4, #6 (2.5, 3) |

54 |

6.10 |

|

MTS-0 |

#8, #10 (4, 5) |

151 |

17.1 |

|

MTS-1 |

1/4 (6) |

432 |

48.8 |

|

MTS-2 |

5/16 (8) |

907 |

102 |

|

MTS-3 |

3/8 (10) |

1362 |

154 |

|

MTS-4 |

1/2 (12) |

2477 |

280 |

|

MTS-5 |

5/8 (14) |

2871 |

324 |

|

MTS-6 |

9/16,5/8(15) |

4698 |

531 |

|

MTS-7 |

3/4 (18) |

10440 |

1180 |

|

MTS-8 |

7/8, 1 (20) |

14000 |

1582 |

*Phillips recommends NOT exceeding 50% of the Minimum Ultimate Driver BitTorque for optimum bit life.

Values shown in the tables are to be used as a guide only. They are subject to change without notice. Please refer to the appropriate Phillips drive systems standards for current information.

Example Application: M6 Socket Head Cap Screw, Alloy Steel

|

System |

Mortorq® Super |

Hex Socket |

Torx Plus® |

|---|---|---|---|

|

Screw |

M6 |

M6 |

M6 |

|

Drive Size |

MTS-1 |

5 |

30IP |

|

Reference Diameter "A" (mm) |

6.11 |

5.77 |

5.61 |

|

Head Diameter (mm) |

10.00 |

10.00 |

10.00 |

|

Head Height (mm) |

4.60 |

5.93 |

5.93 |

|

Head Volume (cm3) |

0.3097 |

0.3720 |

0.3996 |

|

Penetration "D" (mm) |

1.62 |

3.36 |

2.67 |

|

Penetration Factor (D:A%) |

27% |

58% |

48% |

|

Surface Area in Contact |

5.48 |

3.290 |

2.452 |

|

Surface Area in Contact |

10.968 |

3.290 |

2.452 |

The table above shows that the drive contact surface area increases while the head height decreases. Savings result in less materials usage in the screw and mating components around tightly packed subassemblies. Removal torque capability is increased due to an even larger removal wall surface area in contact with the driver bit.

The table above shows that the drive contact surface area increases while the head height decreases. Savings result in less materials usage in the screw and mating components around tightly packed subassemblies. Removal torque capability is increased due to an even larger removal wall surface area in contact with the driver bit.

Mortorq® Super

Spiral Drive System

Mortorq® Super Spiral Drive System

Vs. Hex Socket

Mortorq® Super Spiral Drive System

Vs. Torx Plus®