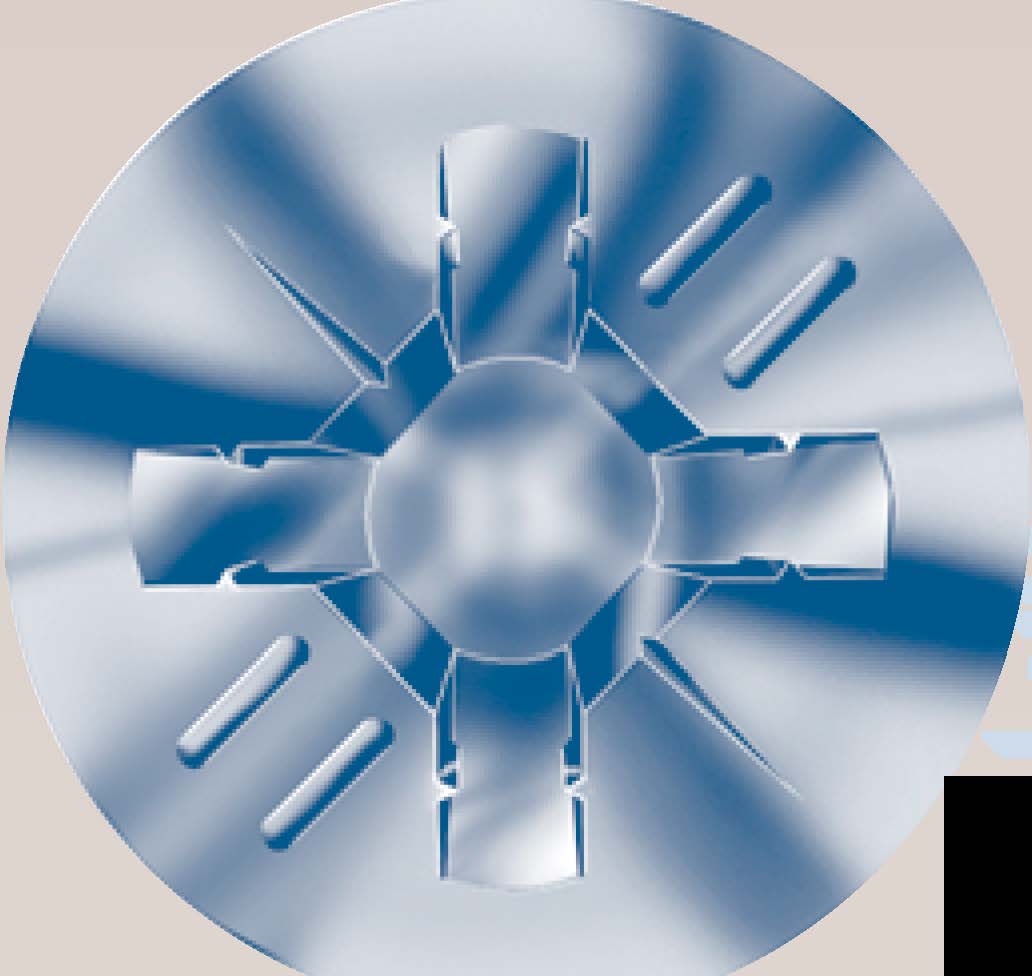

Phillips Square-Driv® The Multifaceted Drive System

Stick fit

Resists cam-out

Lower end-load required

Extended driver tool life

Multi-drive system for field serviceability

(Phillips, Pozidriv®, ACR® Phillips II®, and Square bits are compatible)

Vertical ribs contained within combination recess

Combination ribbed driver bits

Defined head markings for identification

Transportation

Power Management

Appliance

Do-it-Yourself

Home Construction

Revolutionizing fastener drive technology bit by bit. Continuous improvement. It's the key to "Total Quality Concepts." But quality is not limited to manufacturing. Design quality is also crucial, especially for fastener drive systems for high-speed mass production of fastener-held assemblies.

Revolutionizing fastener drive technology bit by bit. Continuous improvement. It's the key to "Total Quality Concepts." But quality is not limited to manufacturing. Design quality is also crucial, especially for fastener drive systems for high-speed mass production of fastener-held assemblies.

Introducing the Phillips Square-Driv® "multi-national recess." Designed to meet the demanding needs of Manufacturing Engineers worldwide, the innovative Phillips Square-Driv fastener drive system design combines the classic Phillips® cruciform recess and the popular square recess. The result: a highly efficient and functional "multi-driver serviceable recess."

Square Drive, Phillips, ACR® Phillips II® and PozidriV® cross-recessed driver bits can also drive Phillips Square-Driv fasteners. The system's patented recess reduces the number of drivers for the popular range of fasteners to just 3 driver sizes. (Eight are required for the hex lobular style of recess.) Fewer required drivers reduce operator error and confusion.

A larger cross-section means greater strength. The Phillips Square-Driv system's increased driver bit cross-section significantly increases the longevity of the driver bit, reducing overall tool costs.

A larger cross-section means greater strength. The Phillips Square-Driv system's increased driver bit cross-section significantly increases the longevity of the driver bit, reducing overall tool costs.

Combination square/cruciform-recess design with anti-cam-out ribs (ACR®) enhances driver bit torque capability. Fasteners can be controlled at higher torque levels for optimum clamp loads without driver bit fatigue failures, which can damage components and cause injuries.

User-friendly "Stick Fit" design improves operator control. The typically demanding operator guidance of drill screws or thread-forming screws during assembly is now far easier and safer with the Phillips Square-Driv system's enhanced "Stick Fit'' of the driver and the screw recess. The patented ACR feature ensures minimal end loads are required to keep the driver engaged in the recess.

"Stick Fit" design also ensures alignment during the screw-driving operation. Precise axial alignment reduces driver "gun runs" when the screw point won't remain online or the driver cams out the recess, often resulting in costly component damage and operator injury.