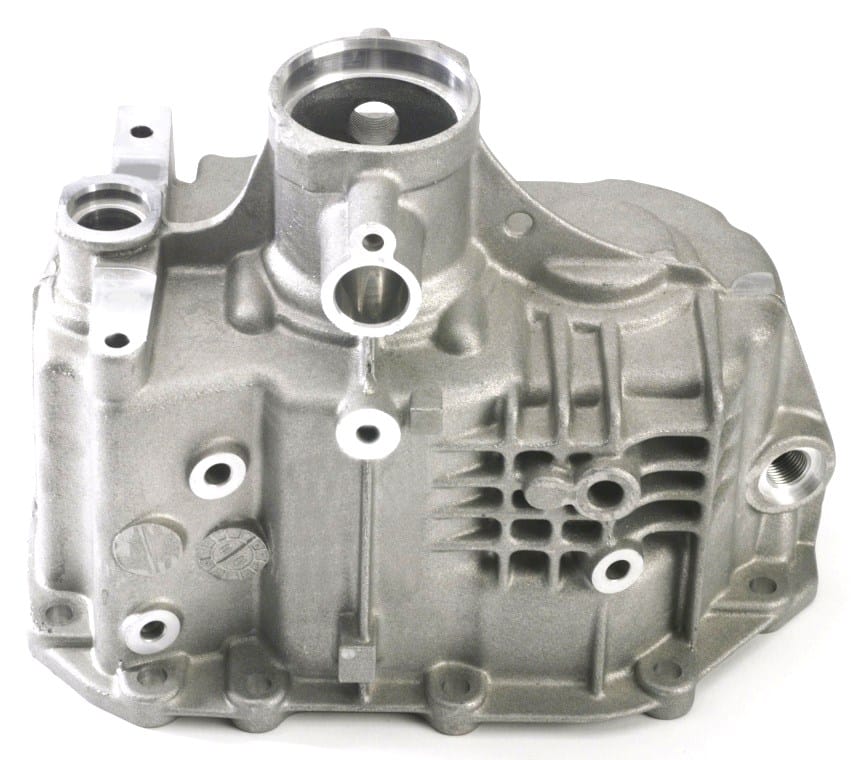

For Magnesium, Aluminum & Reinforced Plastics

One screw used in multiple materials (upon engineering evaluation)

Low installation torque in light metals

Improved vibrational resistance

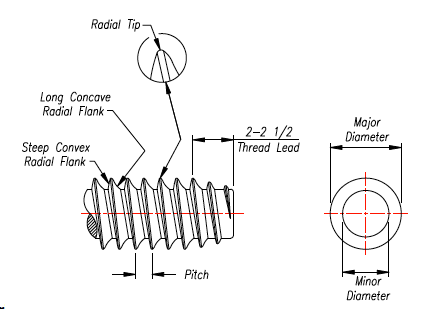

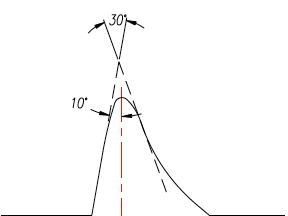

Unique radius flank thread form

Asymmetrical thread with thin angled tip

Narrow pitched thread spacing

The REMFORM® II™ “F” screw utilizes the efficient thread form of the standard REMFORM® II™ fastener but employs finer thread pitch spacing to suit magnesium, soft aluminum, thermoset plastics, and other low ductility materials. The narrow tip angle minimizes the disturbance of a low ductility nut member. The finer thread spacing of REMFORM® II™ “F” screws is advantageous in thermoplastic applications where the length of engagement is less than optimal.

Metric Series

|

SIZE |

PITCH |

MAJOR DIA. |

MINOR DIA. |

|

|---|---|---|---|---|

|

Max. |

Min. |

|||

|

1.0 |

0.30 |

1.07 |

1.00 |

0.68 |

|

1.2 |

0.40 |

1.27 |

1.20 |

0.81 |

|

1.4 |

0.45 |

1.47 |

1.40 |

0.95 |

|

1.6 |

0.50 |

1.70 |

1.60 |

1.08 |

|

1.8 |

0.55 |

1.90 |

1.80 |

1.22 |

|

2.0 |

0.60 |

2.10 |

2.00 |

1.33 |

|

2.2 |

0.70 |

2.30 |

2.20 |

1.47 |

|

2.5 |

0.70 |

2.60 |

2.50 |

1.68 |

|

3.0 |

0.80 |

3.10 |

3.00 |

2.02 |

|

3.5 |

0.95 |

3.60 |

3.50 |

2.37 |

|

4.0 |

1.05 |

4.10 |

4.00 |

2.71 |

|

5.0 |

1.25 |

5.15 |

5.00 |

3.40 |

|

6.0 |

1.40 |

6.15 |

6.0 |

4.09 |

|

7.0 |

1.55 |

7.15 |

7.00 |

4.78 |

|

8.0 |

1.75 |

8.15 |

8.00 |

5.46 |

|

10.0 |

2.25 |

10.15 |

10.00 |

6.82 |

Inch Series

|

SIZE |

PITCH |

MAJOR DIA. |

MINOR DIA. |

|

|---|---|---|---|---|

|

Max. |

Min. |

|||

|

2 |

40 |

0.088 |

0.084 |

0.057 |

|

4 |

32 |

0.114 |

0.110 |

0.074 |

|

6 |

27 |

0.139 |

0.135 |

0.092 |

|

8 |

24 |

0.167 |

0.161 |

0.109 |

|

10 |

21 |

0.193 |

0.187 |

0.127 |

|

12 |

19 |

0.218 |

0.212 |

0.144 |

|

1/4 |

17 |

0.253 |

0.247 |

0.1168 |

|

5/16 |

14 |

0.316 |

0.309 |

0.209 |

The REMFORM® II™ “F” asymmetrical Unique Radius Flank™ thread form has the thread-forming advantages of a 30° thread without the difficulty of manufacturing a 30° thread.

REMFORM® II™ “F” screws employ the Unique Radius Flank™ asymmetrical thread form shown in the drawing to the right. The leading thread flank is most influential in forming the mating thread. The intercepting radius form on the leading flank is there to promote efficient material displacement and material flow. The pressure flank that opposes the fastener head is engineered to resist pull-out forces, whether applied by a tensile load or induced by torque. The steep pressure flank has a subtle radius designed to increase resistance to pullout and to efficiently develop tension. It also provides excellent material contact, resulting in a high resistance to the stripping of internal threads. In applications where the failure mode is fastener fracture, the high torsional strength of REMFORM® II™ “F” fasteners ensures a high failure torque. This unique thread and its narrow tip angle efficiently displace material, requiring minimal energy to form an internal thread. The tip also utilizes a radius to create the internal thread without increasing hoop stress in the plastic.